Comp Cam Solid Roller Valve Lash Specs

Alright gearheads, let's talk about something that might sound a bit intimidating at first: Solid roller valve lash. Sounds like rocket science, right? But trust me, once you get the basics down, it's actually pretty cool. Think of it as giving your engine's valves a tiny little hug – just the right amount, so they can do their job properly without getting squished! So, what's all the fuss about anyway?

What is Valve Lash, Really?

Okay, imagine your engine's valves as little doors that open and close to let air and fuel in, and exhaust out. They're controlled by the camshaft, which has these little bumps (lobes) that push on the valves. Now, here's the thing: metal expands when it gets hot. If there was *no* gap between the rocker arm (the thing pushing on the valve) and the valve stem when the engine is cold, what would happen when it heats up? That valve would stay open all the time! Not good. We need a tiny gap – that's the valve lash.

Think of it like adjusting the strings on a guitar. Too tight, and they'll snap. Too loose, and they won't make a sound. Just the right tension and you get beautiful music. Similarly, proper valve lash ensures your engine "sings" its best tune.

Solid vs. Hydraulic: The Big Difference

Now, there are two main types of valve lifters: hydraulic and solid. Hydraulic lifters are self-adjusting; they use oil pressure to maintain the correct valve lash. Solid lifters? Not so much. They require manual adjustment. Which one is better? Well, it depends on what you want to do with your engine. Hydraulic lifters are great for street cars because they're low maintenance and quiet. But for high-performance engines, especially those running at higher RPMs, solid lifters are often preferred. Why? Because they offer more precise valve control and can handle the stresses of high-performance applications.

Consider this: hydraulic lifters are like having a super forgiving suspension on your car – comfortable but maybe a bit mushy during hard cornering. Solid lifters are like having a stiff, race-tuned suspension – less forgiving, but way more responsive and predictable when pushing the limits.

Why Solid Roller Lifters are Special

Solid roller lifters take things up another notch. They use a small roller bearing on the bottom of the lifter that rides on the camshaft lobe. This reduces friction and allows for more aggressive camshaft profiles, leading to increased horsepower and torque. But with that performance boost comes responsibility. Because there is no hydraulic compensation, valve lash setting is critical.

The Importance of Getting the Specs Right

So, why am I hammering on about these specs? Because getting the valve lash *wrong* can have serious consequences. Too loose, and you'll have noisy valve train, reduced power, and excessive wear on the valve train components. Too tight, and you risk holding the valve open, leading to burnt valves and potentially catastrophic engine damage.

Imagine trying to run a marathon in shoes that are either two sizes too big or two sizes too small. Either way, you're going to have a bad time. Similarly, incorrect valve lash can cripple your engine's performance and longevity.

Finding and Understanding the Specs

Where do you find these magical valve lash specs? The most reliable source is always the camshaft manufacturer. Usually, this information is included with the camshaft itself, or available on their website. If you are running someone else’s combination or are buying used parts, you will need to research diligently. Be sure to find the manufacturer and part number for your camshaft.

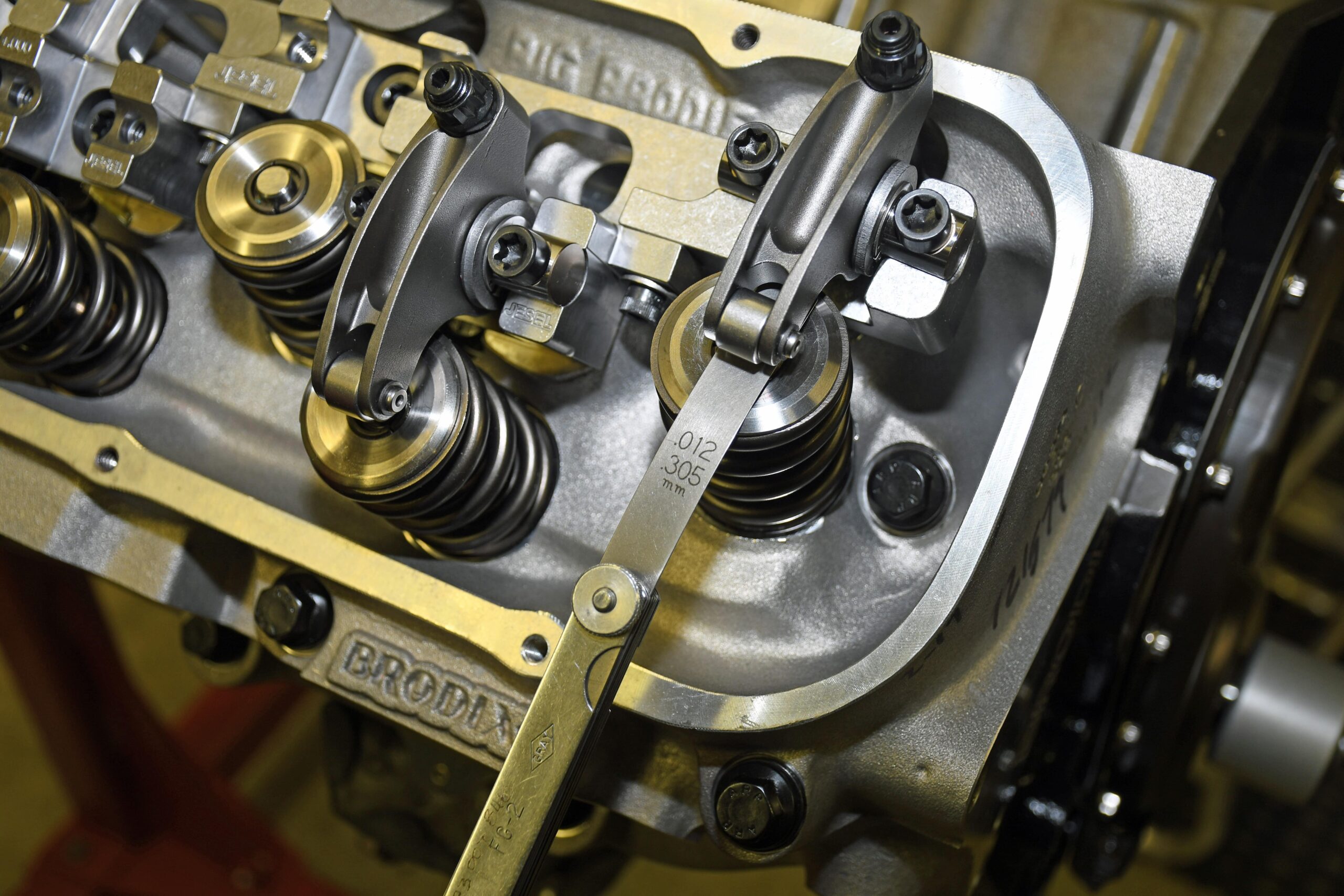

Pay close attention to whether the specs are for a cold or hot engine. This is crucial! The specs will typically be listed as a range, for example, "0.016" - 0.018" cold." This means you should aim for a lash setting within that range when the engine is cold.

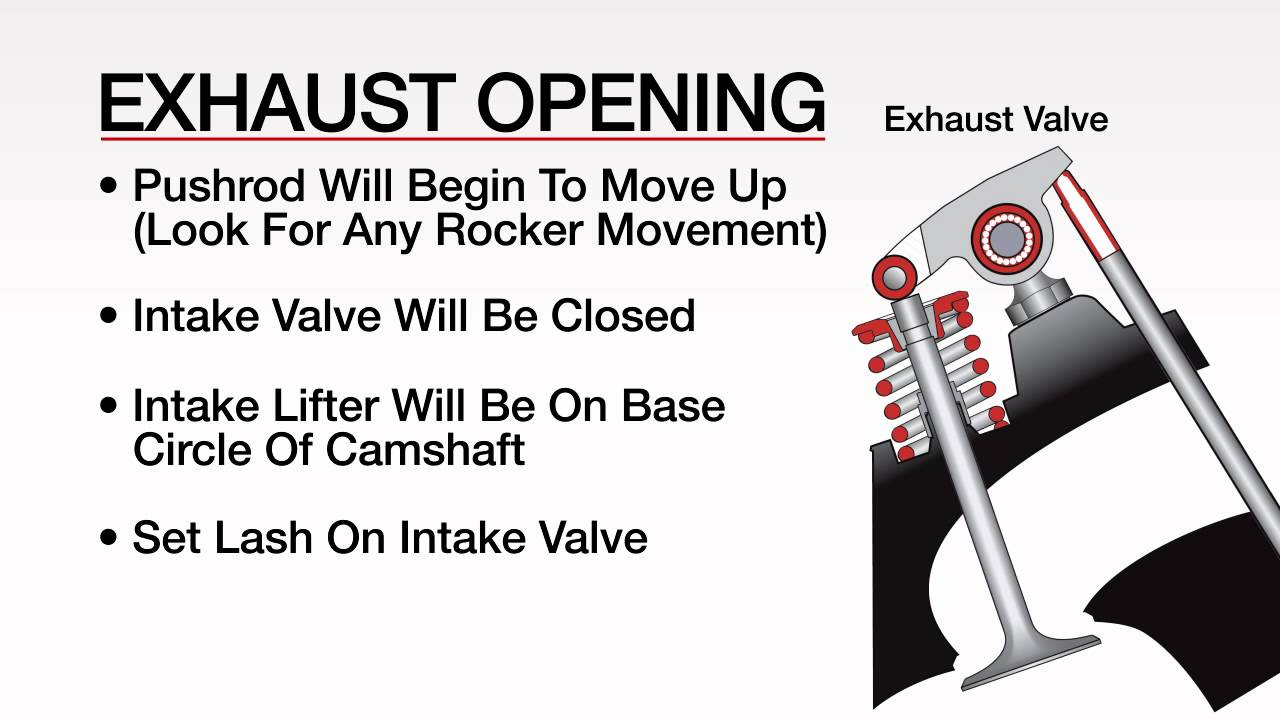

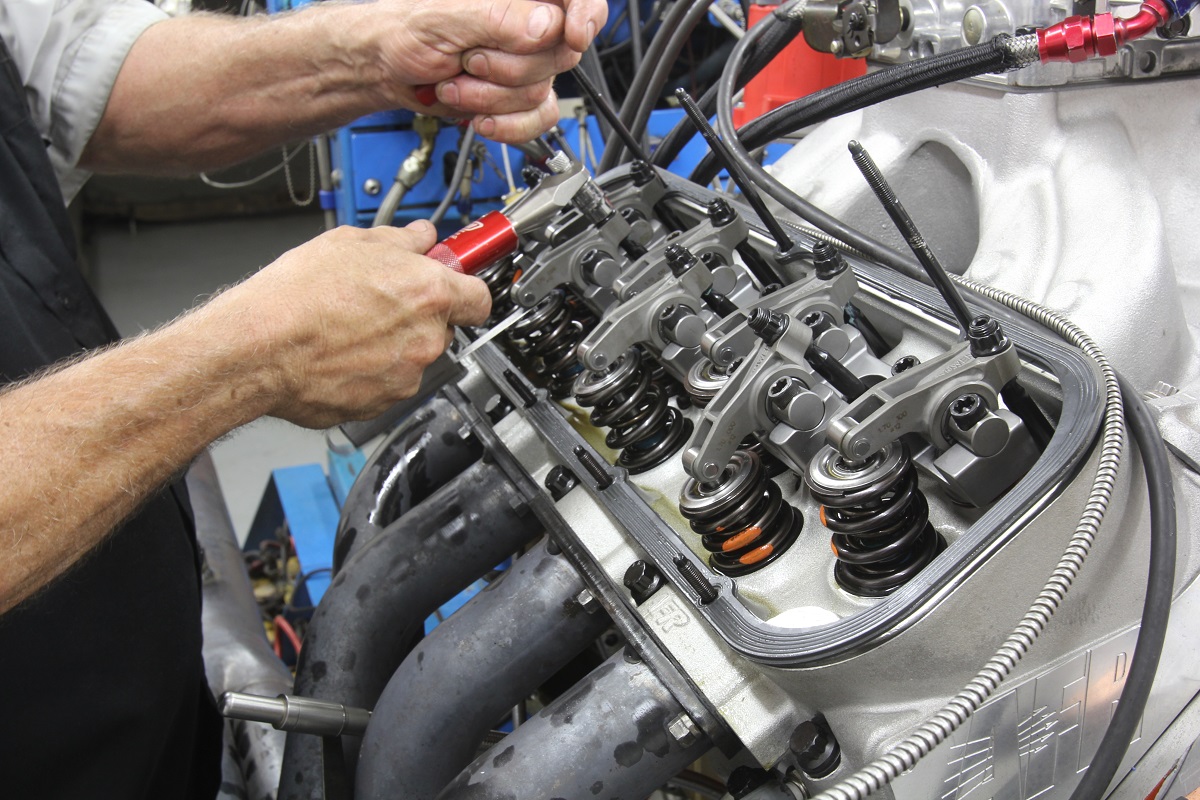

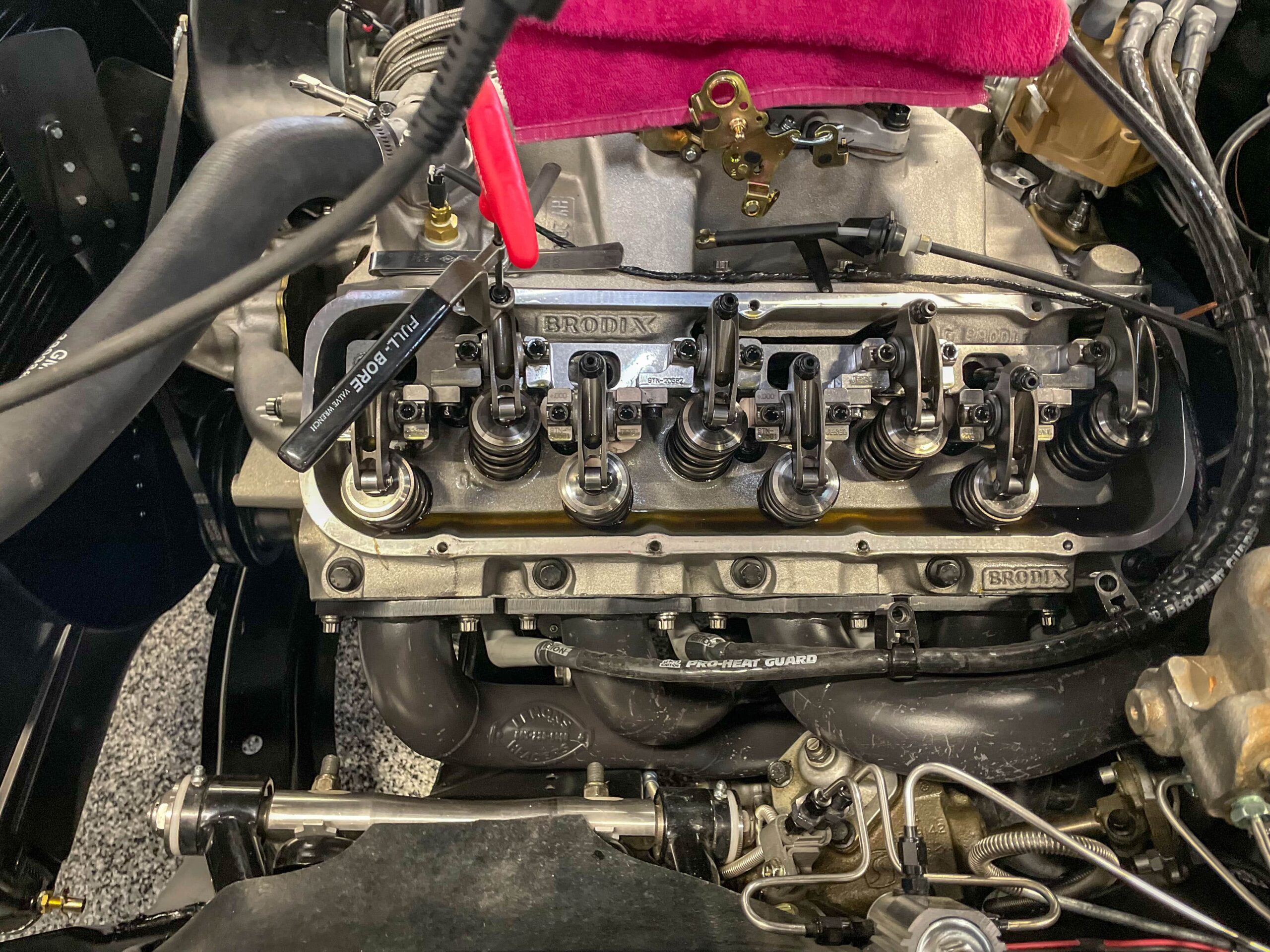

The Adjustment Process (Simplified)

I won't go into the nitty-gritty of the adjustment process here (there are plenty of videos and tutorials online), but the basic idea is to use a feeler gauge to measure the gap between the rocker arm and the valve stem, and then adjust the rocker arm until the gap is within the specified range. It's a precise process, but with patience and the right tools, anyone can do it.

It’s Worth the Effort

Adjusting solid roller valve lash might seem intimidating, but it's a crucial part of maximizing your engine's performance and ensuring its longevity. Think of it as a form of engine fine-tuning, like adjusting the focus on a camera lens to get a perfectly sharp image. When you get it right, you'll feel the difference in your engine's responsiveness, power, and overall smoothness. So, dive in, do your research, and give your engine the love it deserves!

And hey, who knows? You might even find that adjusting valve lash is kind of… therapeutic? Okay, maybe not, but it's definitely rewarding when you hear that engine purring like a happy kitten (or roaring like a lion, depending on your setup!).