Ford 6.2 Oil Dipstick Tube Replacement

Okay, let's talk about something that might seem, well, a little… mundane. Your Ford 6.2L's oil dipstick tube. Yeah, I know, it's not exactly the stuff of high-octane Hollywood blockbusters. But trust me, this little piece of metal is way more important than you think. Think of it like the trusty goalie on your favorite hockey team – doesn’t get all the glory, but if it fails, you're in trouble!

Why should you, a busy person with way more exciting things to do, care about a simple tube? Because a busted or broken dipstick tube can lead to a whole heap of engine headaches, and nobody wants those! Think of it like this: neglecting a small crack in your foundation is like ignoring that weird noise your car makes – it's only going to get worse (and more expensive!).

Why a Healthy Dipstick Tube Matters

Let's break it down. Your dipstick tube has two main jobs:

1. Accurate Oil Level Readings

This is the obvious one. It’s the little track your dipstick travels down to tell you how much oil is sloshing around in your engine. An intact tube ensures the dipstick goes to the proper depth, giving you an accurate reading. A bent, broken, or missing tube? Well, you might as well be guessing the oil level with a blindfold on. Imagine baking a cake without measuring the ingredients – you might end up with something edible, but it’s probably not going to be award-winning!

2. Preventing Contamination

This is where things get a little more serious. A cracked or damaged tube becomes an open invitation for dirt, dust, and other nasty contaminants to sneak into your engine. Think of it like leaving your house door wide open during a sandstorm – you're going to have a mess to clean up! These contaminants act like sandpaper inside your engine, causing premature wear and tear on vital components. And trust me, engine repair is never cheap.

Plus, a missing or cracked tube can also lead to oil leaks. Nobody wants to see a puddle of oil forming under their truck, especially not on your driveway. It's not only messy but also environmentally unfriendly and potentially a sign of bigger problems to come. It’s like having a leaky faucet – annoying, wasteful, and something you should fix sooner rather than later.

Signs Your Dipstick Tube Needs Replacing

So, how do you know if your trusty dipstick tube is on its last legs? Keep an eye out for these telltale signs:

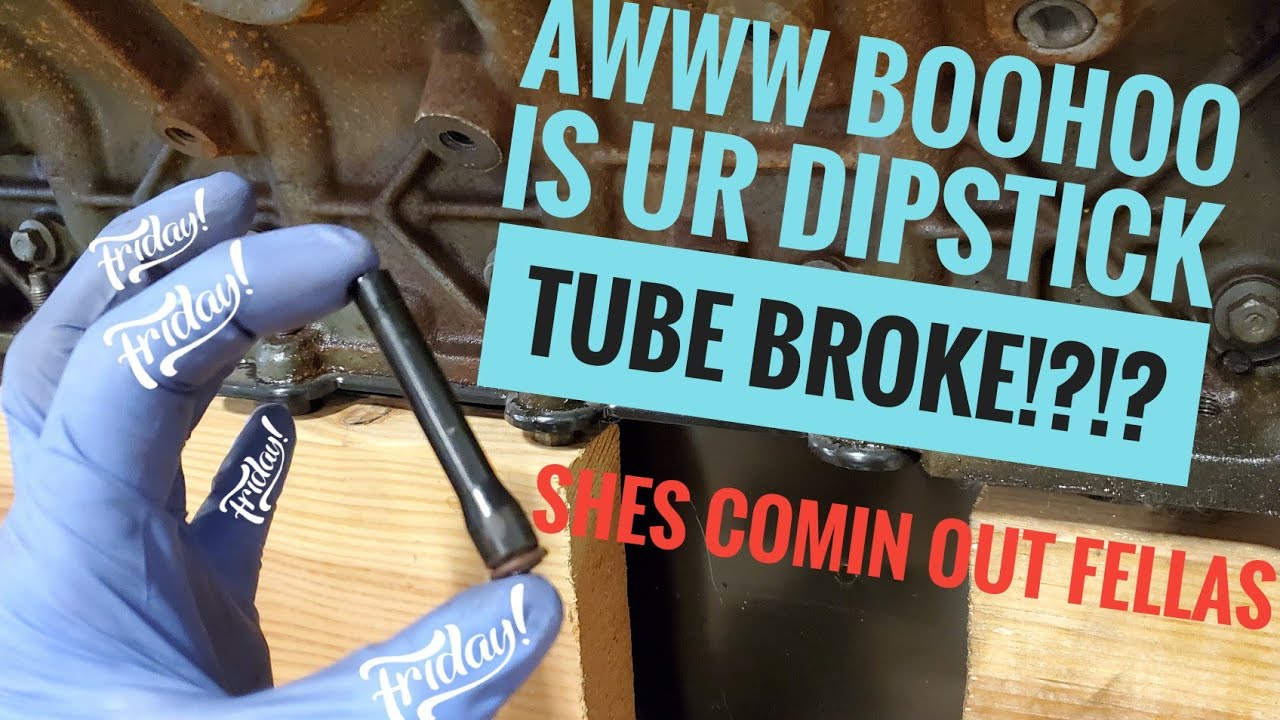

- Visible Cracks or Breaks: This is the most obvious sign. If you see any physical damage to the tube, it's time for a replacement. It’s like seeing a crack in your phone screen – you know it’s only going to get bigger.

- Difficulty Inserting or Removing the Dipstick: If the dipstick feels tight, sticky, or refuses to go in all the way, the tube might be bent or corroded internally. Think of trying to squeeze into your favorite jeans after Thanksgiving dinner – something’s not quite right!

- Oil Leaks Around the Tube Base: If you notice oil pooling around the base of the tube where it enters the engine block, the seal might be compromised. This is like a dripping nose – an obvious sign something’s amiss.

- Inaccurate Oil Level Readings: If you consistently get inconsistent or unusually low oil level readings despite having recently added oil, the dipstick tube might be the culprit. It’s like your bathroom scale suddenly telling you you've lost 50 pounds overnight – you know it’s probably lying!

The Replacement Process (Simplified!)

Okay, now for the part that might make you break a sweat. Replacing the dipstick tube. While it *can* be a DIY project, it's important to be honest with yourself about your mechanical skills. If you're comfortable changing your own oil, you *might* be able to tackle this. But if you struggle to tell a wrench from a screwdriver, it's best to leave it to the professionals. It's like attempting to cut your own hair after watching a YouTube video – sometimes it works out, sometimes you end up looking like a lawnmower attacked you!

Here’s a general overview of what the process usually involves:

- Gather Your Supplies: You'll need a new dipstick tube (make sure it's the right one for your specific Ford 6.2L!), some basic tools (sockets, wrenches, pliers), and maybe some penetrating oil to help loosen stubborn bolts. Think of it like prepping to bake that cake – you need all your ingredients ready to go.

- Remove the Old Tube: This often involves removing any surrounding components that might be in the way, like brackets or hoses. Be careful not to damage anything else in the process. It's like carefully unwrapping a fragile gift – you don’t want to accidentally break anything!

- Clean the Mounting Surface: Thoroughly clean the area where the new tube will be installed. This ensures a good seal and prevents leaks. It’s like preparing a canvas before painting – you want a clean surface for optimal results.

- Install the New Tube: Carefully insert the new tube into the engine block, making sure it's properly seated. You might need to use a rubber mallet to gently tap it into place. It’s like fitting the last piece of a puzzle – it should fit snugly and securely.

- Secure the Tube: Tighten any bolts or screws that hold the tube in place. Don't overtighten them, as this could damage the tube or the engine block. Think of it like tightening the lid on a jar – snug is good, crushed is bad!

- Reinstall Removed Components: Put back any brackets, hoses, or other components you removed earlier. Make sure everything is properly connected and secure. It’s like putting the furniture back in place after cleaning your house – you want everything back where it belongs.

- Check for Leaks: Start the engine and let it run for a few minutes. Carefully inspect the base of the dipstick tube for any signs of oil leaks. If you see any, tighten the bolts or screws a little more. It’s like taste-testing your cake before serving it – you want to make sure everything is just right.

Important Note: Always consult your vehicle's repair manual for specific instructions and torque specifications. Every vehicle is different, and following the correct procedure is crucial to avoid damaging your engine.

Why Bother DIY-ing? (And When Not To!)

The big question: should you tackle this yourself? Here's a quick guide:

DIY All-Star: If you're comfortable working on your car, have the right tools, and enjoy the challenge, then go for it! You'll save some money on labor costs, and you'll get the satisfaction of knowing you fixed it yourself. It’s like baking your own birthday cake – rewarding and delicious!

Professional Bound: If you're not confident in your abilities, or if the job seems too complicated, don't hesitate to take it to a trusted mechanic. Sometimes, it's better to admit defeat and let the experts handle it. It’s like hiring a professional caterer for your wedding – you want everything to be perfect, and you don’t want to stress about it!

The Long-Term Benefits

Replacing your Ford 6.2L's oil dipstick tube might seem like a small thing, but it can have a big impact on the health and longevity of your engine. By ensuring accurate oil level readings and preventing contamination, you'll be protecting your investment and avoiding costly repairs down the road. It’s like flossing your teeth – it might seem like a chore, but it prevents cavities and keeps your smile healthy for years to come!

So, there you have it! The not-so-secret world of the oil dipstick tube. It might not be glamorous, but it's definitely important. Take care of this little component, and it will take care of your engine. And that's something worth caring about.