How Thick Was The Steel On The Titanic

Okay, so you're probably thinking, "The Titanic? Steel thickness? Why should I care?" Well, stick with me, because it's actually way more interesting than it sounds. Think of it like this: knowing how thick the steel on the Titanic was is like knowing how many layers of cake are in your favorite dessert. It's all about understanding the fundamental ingredients that made something so grand, and ultimately, what went wrong.

So, How Thick Are We Talking?

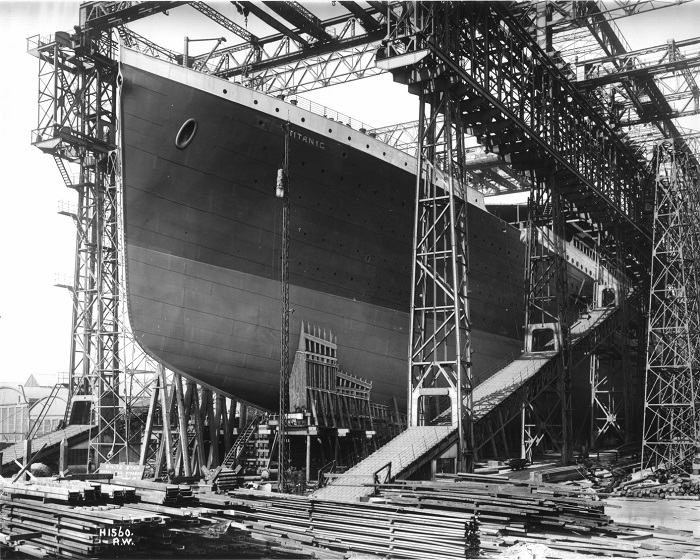

The Titanic's hull wasn't made of just one uniform slab of metal. It varied! Imagine building a house – you wouldn't use the same thickness of wood for the walls as you would for the roof, right? Same principle here.

The steel plating used was primarily around 1 inch (2.5 cm) thick. Now, 1 inch might not *sound* like much. Think about the thickness of a quarter. Stack about 4 of those on top of each other – that's roughly an inch. That was the armor protecting thousands of souls on the open ocean!

However, the thickness wasn't consistent throughout the ship. Some areas, particularly around the boiler rooms and other stress points, had plating that was thicker, reaching up to 1.5 inches (3.8 cm) or even more.

Why Does It Even Matter?

Good question! It all boils down to strength and vulnerability. Imagine your car bumper. It’s there to protect you in a minor fender-bender, right? The Titanic's hull was its bumper against the vast and unforgiving Atlantic. The steel was supposed to be strong enough to withstand the normal hazards of ocean travel, things like waves, minor collisions with debris, and the general wear and tear of being a giant metal beast sailing the seas.

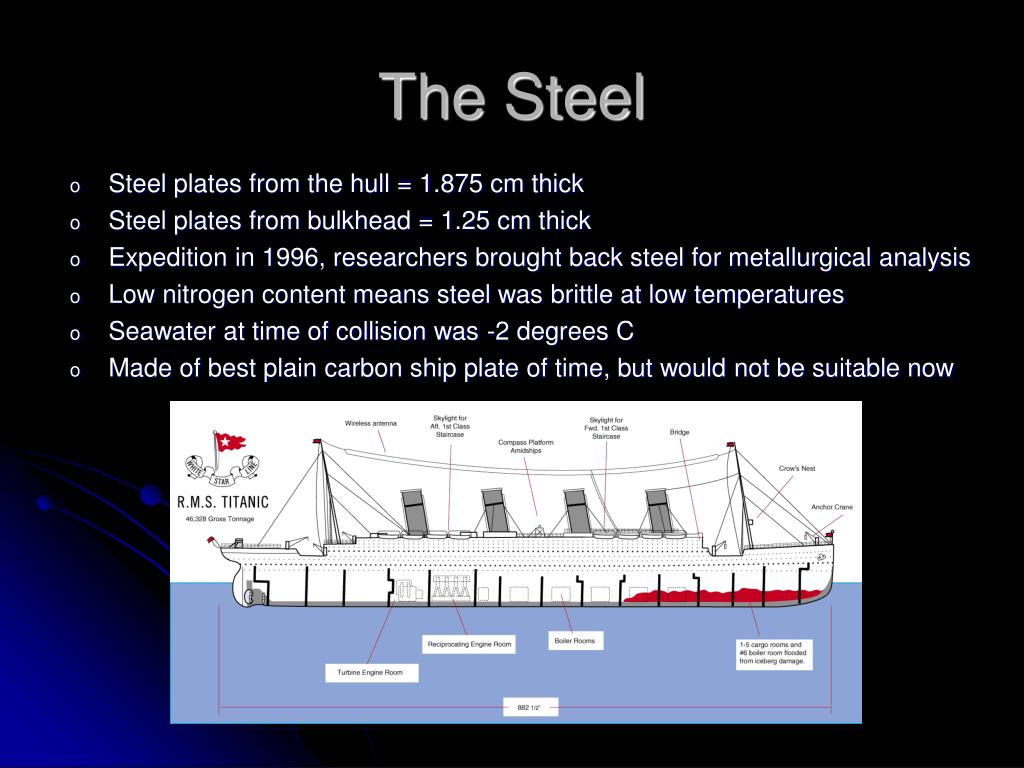

The problem wasn't just the thickness, though. It was the quality of the steel itself. Here's where things get really interesting.

The steel used in the Titanic was known as mild steel, and it contained a relatively high amount of sulfur. Think of it like making cookies with slightly off ingredients. They *look* like cookies, but they might be a little too crumbly, a little too hard, or just… not quite right.

The high sulfur content made the steel more brittle, especially in cold temperatures. And guess what the North Atlantic waters were like that fateful night? Freezing cold! The steel's brittleness made it more susceptible to cracking upon impact.

The Iceberg: The Unforgiving Test

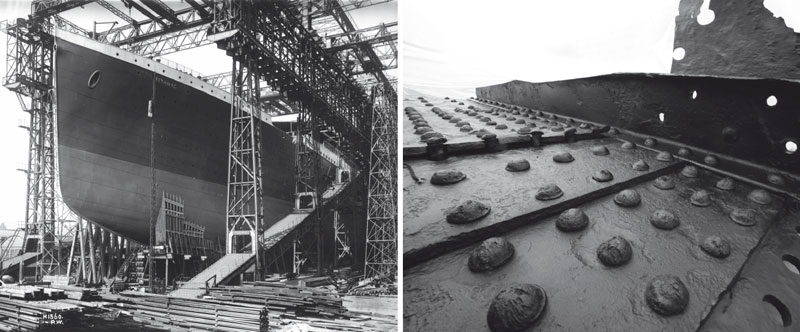

Now, picture this: a giant iceberg lurking beneath the surface. The Titanic, sailing at a relatively high speed, strikes it a glancing blow. If the steel had been of higher quality and perhaps even a bit thicker, the damage might have been minimized. Maybe just a few dents, a bit of flooding, and a slightly delayed arrival in New York.

But the combination of thinner-than-ideal steel and its brittleness created a perfect storm. The iceberg didn't just bounce off; it created a series of narrow breaches along the ship's hull, opening the floodgates (literally) to disaster.

So, What's the Takeaway?

Understanding the Titanic's steel thickness is more than just a historical trivia fact. It's a lesson in materials science, engineering, and the importance of quality control. It's a reminder that even the most ambitious creations can be brought down by seemingly small flaws.

Think of it next time you're buying something – from a car to a kitchen appliance. Are you just looking at the flashy exterior, or are you also considering the quality of the materials used inside? The Titanic’s story, down to the thickness of its steel, teaches us that details matter. They can be the difference between success and catastrophic failure. And maybe, just maybe, understanding these details can help us build a better, safer future.