Kubota Fuel Shut Off Solenoid Problems

Ever feel like your day is going swimmingly, you're about to accomplish something awesome, and then… *poof* …nothing? Like when you're about to finally parallel park perfectly and someone steals your spot? Or when you're heating up that late-night pizza and the microwave dies right as it starts? That, my friend, is kinda like what happens when your Kubota's fuel shut off solenoid decides to take an unscheduled vacation.

Except, instead of a sad pizza craving, you're staring at a tractor that's as useful as a paperweight. A very expensive, very orange paperweight.

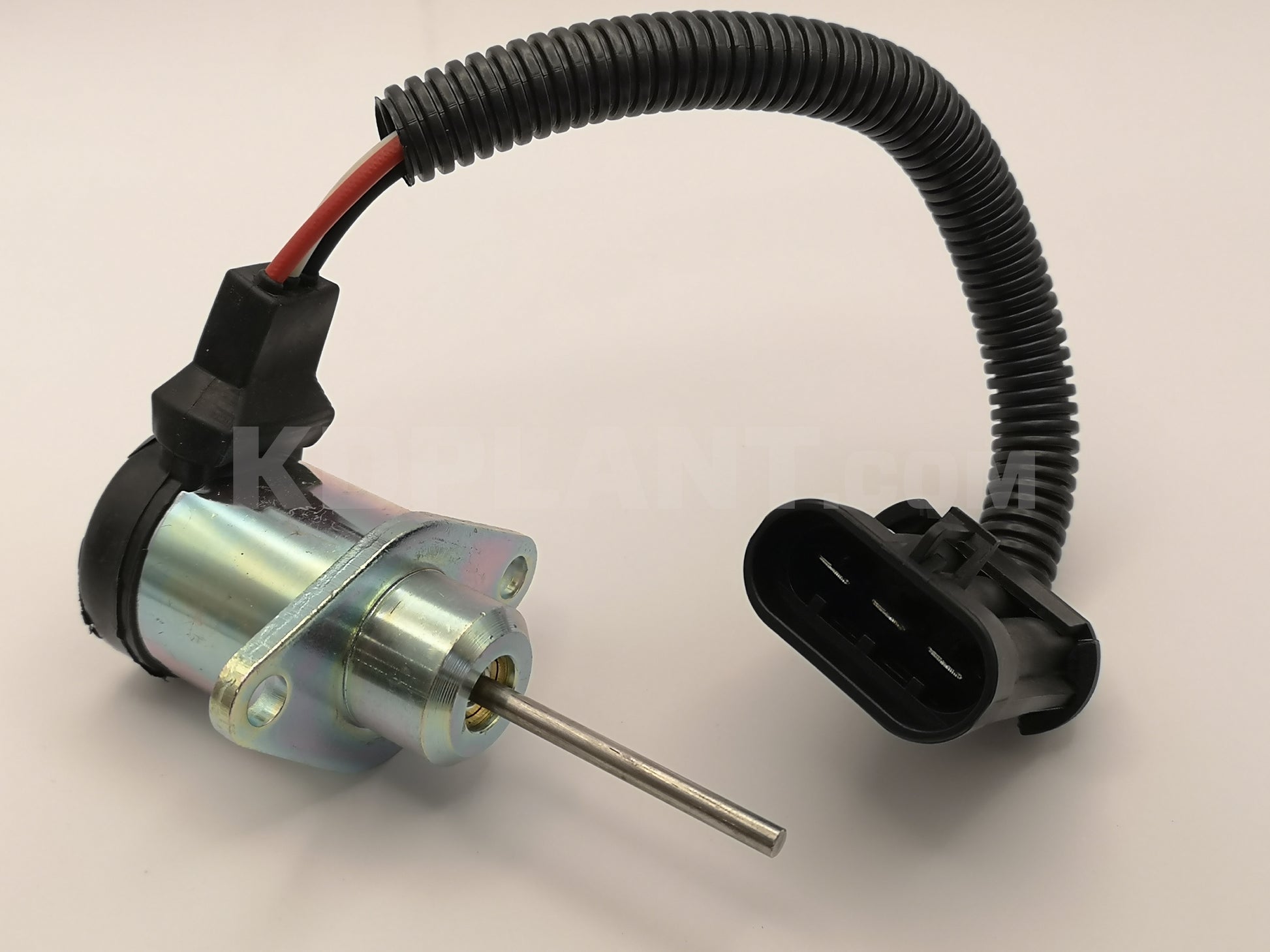

What in the Heck is a Fuel Shut Off Solenoid Anyway?

Okay, so "fuel shut off solenoid" sounds like something NASA would use to launch a rocket. In reality, it’s a much simpler, but equally important, critter. Think of it as the gatekeeper of the diesel fuel line in your Kubota. Its sole purpose is to control the flow of fuel to the engine. When you turn the key to start, the solenoid opens up, fuel rushes in, and your trusty tractor roars to life.

Turn the key off? The solenoid slams shut, cutting off the fuel supply and stopping the engine. It's like the emergency brake for your fuel system.

Now, you might be thinking, "Why can't I just turn a knob or something?" Well, you *could*, but that would be about as convenient as texting your grandma using Morse code. The solenoid automates the process, making starting and stopping your tractor as easy as, well, turning a key.

The Grim Reality: Solenoid Troubles

So, everything’s perfect until… it isn't. These solenoids, bless their little electronic hearts, aren't exactly known for their undying loyalty. They can, and often do, throw a wrench (or a handful of dirt) into your plans.

Why? A few reasons. Let's break it down, shall we?

- Electrical Gremlins: These solenoids rely on electricity to do their job. A loose wire, a corroded connection, or a bad ground can leave them hanging, like a politician on a broken promise. Suddenly no fuel.

- Mechanical Mishaps: Inside the solenoid is a plunger (or valve) that moves to open and close the fuel line. Sometimes, this plunger gets sticky, gunked up, or just plain tired. Picture it like that one coworker who always needs a few extra minutes to get started in the morning.

- Plain Old Wear and Tear: Everything eventually wears out, right? It's like that favorite pair of jeans you've had for ten years – eventually, the fabric gives way. Solenoids are no different. They're constantly working, so they’re bound to fail eventually.

The Dreaded Symptoms: How to Tell if Your Solenoid is on the Fritz

Okay, so how do you know if your fuel shut off solenoid is staging a mutiny? Here are a few telltale signs that something’s amiss:

- The Silent Treatment: The most obvious symptom is that your Kubota simply won't start. You turn the key, the engine cranks, but it just won't fire up. It's like trying to start a conversation with a teenager who just wants to listen to music.

- The Stall-Out Blues: Your tractor starts fine, runs for a bit, and then suddenly dies. This is like a cruel joke, especially when you're halfway through mowing the lawn. It starts, gives you hope, then says "nope, I'm done."

- The Intermittent Issue: This is the most infuriating symptom of all. Sometimes it starts, sometimes it doesn't. It's like trying to predict the weather based on a coin flip. This makes diagnosis a real pain in the posterior.

- The Clicking Conundrum: You might hear a clicking sound coming from the solenoid when you turn the key. This *could* indicate that the solenoid is getting power but struggling to open. It's like the solenoid is trying to lift weights that are just too heavy.

Troubleshooting Time: Becoming a Tractor Whisperer

Alright, so you suspect your fuel shut off solenoid is the culprit. Before you start tearing things apart like a caffeinated toddler in a toy store, let's try some basic troubleshooting.

- Check the Obvious Stuff: Is your fuel tank full? Seriously. Don't laugh, it happens to the best of us. Make sure the fuel shut-off valve (if your tractor has one) is open. Basically, do a quick sanity check to rule out the dumb stuff.

- Trace the Wires: Grab your trusty multimeter (or a test light) and check the wiring leading to the solenoid. Make sure you're getting power when the key is in the "on" position. Look for loose connections, corroded terminals, or damaged wires. Imagine you’re a detective solving a mystery, except the clues are wires and voltage readings.

- Listen Carefully: With the key in the "on" position, put your ear close to the solenoid. You should hear a distinct "click" as it activates. If you don't hear anything, it's a pretty good sign the solenoid isn't getting power or is internally kaput.

- The Direct Power Test (Use Caution!): This is a bit more advanced, but you can try applying direct power to the solenoid from the battery (using jumper wires). Be extremely careful not to short circuit anything! If the solenoid clicks when you apply direct power, it means the solenoid itself is probably okay, and the problem lies in the wiring or the control circuit. If it still doesn't click, it's likely a dead solenoid.

- The Gentle Tap: Sometimes, a sticky plunger can be freed up with a gentle tap. Lightly tap the solenoid body with a wrench or screwdriver handle while someone tries to start the tractor. It's like giving it a little encouragement (or a mild threat). This is a long-shot, but hey, it’s worth a try!

The Moment of Truth: Replacement or Repair?

So, you've done your due diligence. You've poked, prodded, and tested. Now what? Well, you have a few options:

- Replacement: This is usually the easiest and most reliable solution. Fuel shut off solenoids aren't terribly expensive (compared to, say, a new engine), and replacing one is a relatively straightforward process. Just make sure you get the correct part for your Kubota model. It's like ordering pizza - make sure you get the right size and toppings.

- Repair (Maybe): In some cases, you *might* be able to repair a fuel shut off solenoid. This usually involves cleaning the plunger and the solenoid body. However, this is often a temporary fix, and the solenoid will likely fail again eventually. Think of it as putting a Band-Aid on a broken leg – it might look okay for a little while, but it's not a long-term solution. Unless you're incredibly mechanically inclined, replacement is the way to go.

Replacing the Solenoid: A Step-by-Step Guide (General Overview)

Alright, so you've decided to replace the solenoid. Here’s a general overview of the process. *Always consult your Kubota's service manual for specific instructions for your model.*

- Gather Your Tools: You'll need a wrench (or socket set), a screwdriver, and maybe a pair of pliers. Safety glasses are also a good idea, because nobody wants diesel fuel in their eye.

- Disconnect the Battery: This is crucial! Disconnecting the battery prevents any accidental electrical shocks. Think of it as putting on your seatbelt before you drive.

- Locate the Solenoid: It's usually located near the fuel pump or the injection pump. Consult your service manual if you're not sure where it is.

- Disconnect the Wiring: Carefully disconnect the wires from the solenoid. Make a note of which wire goes where, or take a picture with your phone. This will save you a headache later.

- Remove the Old Solenoid: Use a wrench or socket to loosen and remove the old solenoid. Be prepared for a little fuel to spill out. Have a rag handy.

- Install the New Solenoid: Install the new solenoid, tightening it securely. Don't overtighten it, or you could damage the threads.

- Reconnect the Wiring: Reconnect the wires to the solenoid, making sure they're connected correctly.

- Reconnect the Battery: Reconnect the battery.

- Test it Out: Turn the key and see if your Kubota starts. If it does, congratulations! You've successfully replaced the fuel shut off solenoid. If it doesn't, double-check your work and consult your service manual.

Prevention is Better Than a Broken Tractor

Okay, so you've conquered the solenoid beast. Now, how can you prevent this from happening again? Here are a few tips:

- Keep it Clean: Regularly inspect the wiring and connections around the solenoid. Clean off any dirt, corrosion, or grime. A little preventative maintenance can go a long way.

- Use Clean Fuel: Dirty fuel can clog up the solenoid and cause it to malfunction. Use a good quality fuel filter and change it regularly.

- Exercise it: If you don't use your Kubota for extended periods, start it up occasionally and let it run for a few minutes. This will help keep the solenoid from getting sticky.

- Consider a Fuel Additive: Some fuel additives can help lubricate the fuel system and prevent corrosion.

Dealing with a faulty fuel shut off solenoid is never fun, but hopefully, this guide has given you the knowledge and confidence to diagnose and fix the problem yourself. Remember, even the most frustrating mechanical issues can be overcome with a little patience, a few tools, and a sense of humor. Now go forth and conquer your Kubota-related challenges!