Mercury Outboard Shift Linkage Diagram

The shift linkage system in a Mercury outboard motor is a critical component responsible for engaging and disengaging the gears, thereby controlling forward, neutral, and reverse propulsion. Understanding its configuration and how it operates is essential for proper maintenance, troubleshooting, and repair. This article provides a detailed overview of a typical Mercury outboard shift linkage system, emphasizing its components, function, and common issues.

Components of the Shift Linkage

The shift linkage is not a single unit, but rather an interconnected system composed of several key parts, each contributing to the overall functionality. Understanding these components is vital to diagnosing and resolving shift linkage problems.

Shift Control Lever

The shift control lever, typically located on the boat's console or side, is the primary input device for the system. This lever allows the operator to select the desired gear: forward, neutral, or reverse. The shift lever's movement translates into mechanical motion that is transmitted through the linkage.

Shift Cable

The shift cable transmits the motion from the shift control lever to the engine. It’s a flexible cable housed within a protective sheath. The cable is connected to the shift control lever at one end and to the shift linkage on the engine at the other. The cable must be properly adjusted to ensure accurate gear engagement.

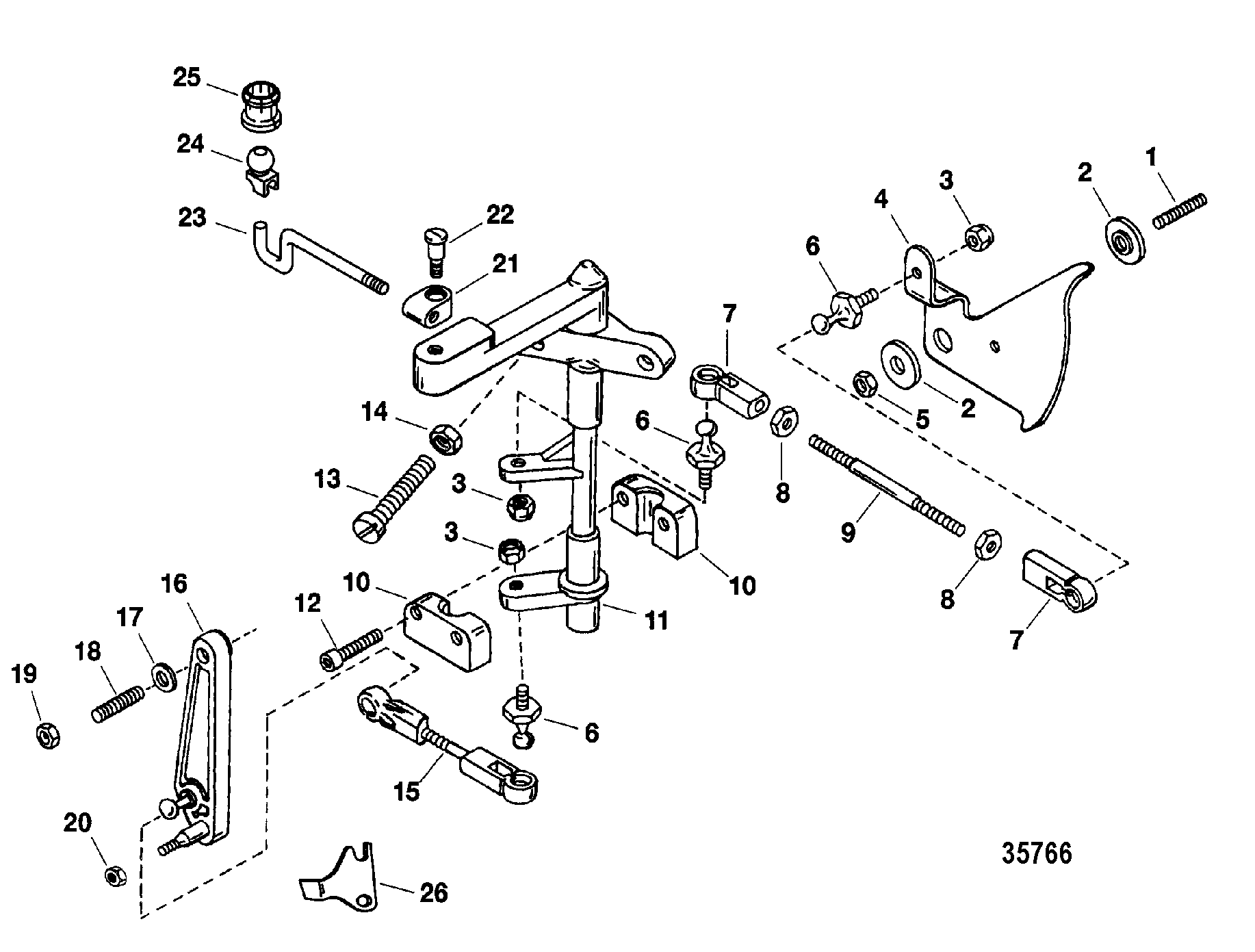

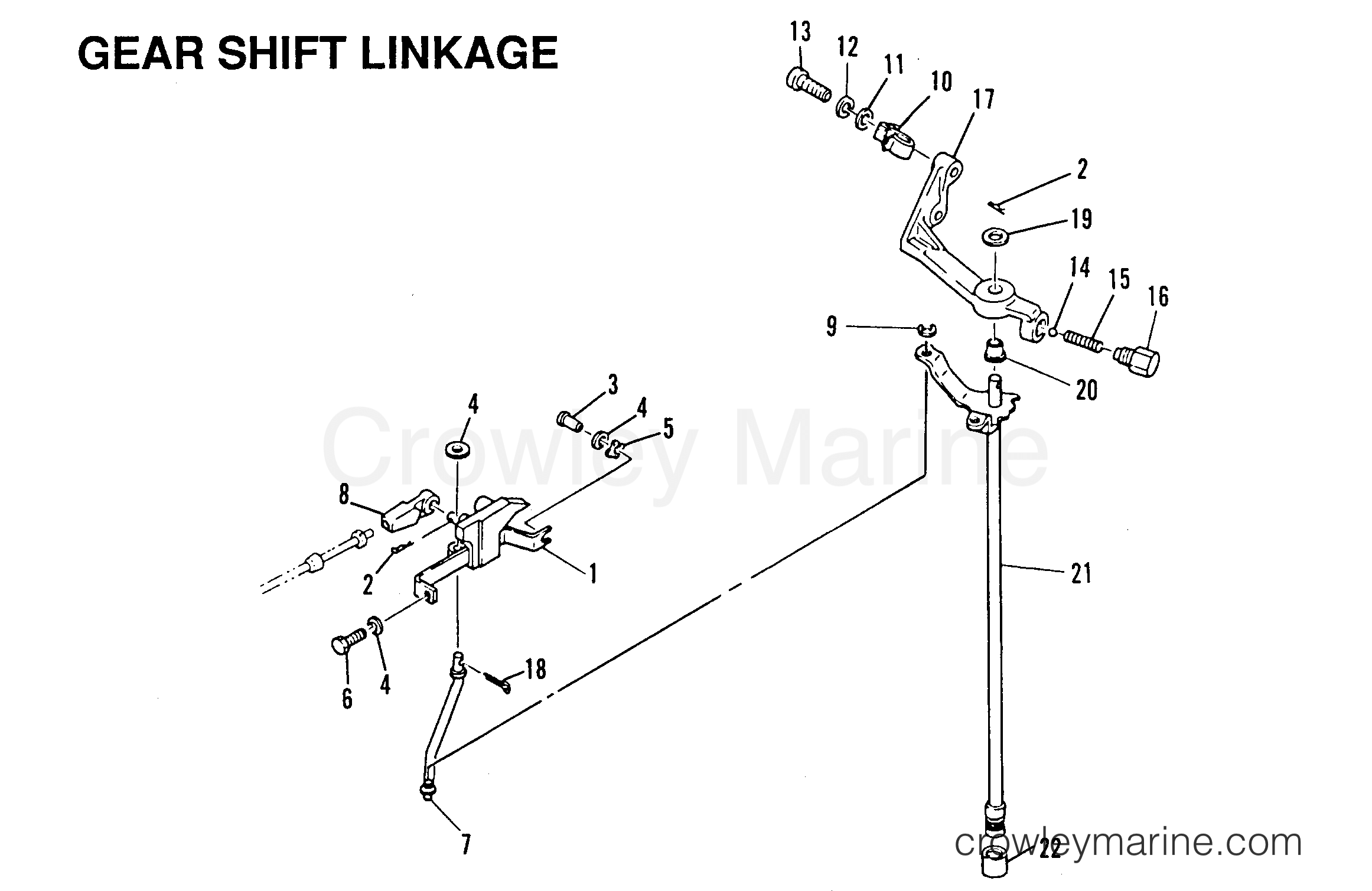

Shift Linkage Rods and Levers

These are a series of metal rods and levers that connect the shift cable to the shift shaft on the lower unit of the outboard. The design varies depending on the specific Mercury outboard model. Their purpose is to translate the linear motion of the shift cable into a rotational motion to control the shift shaft.

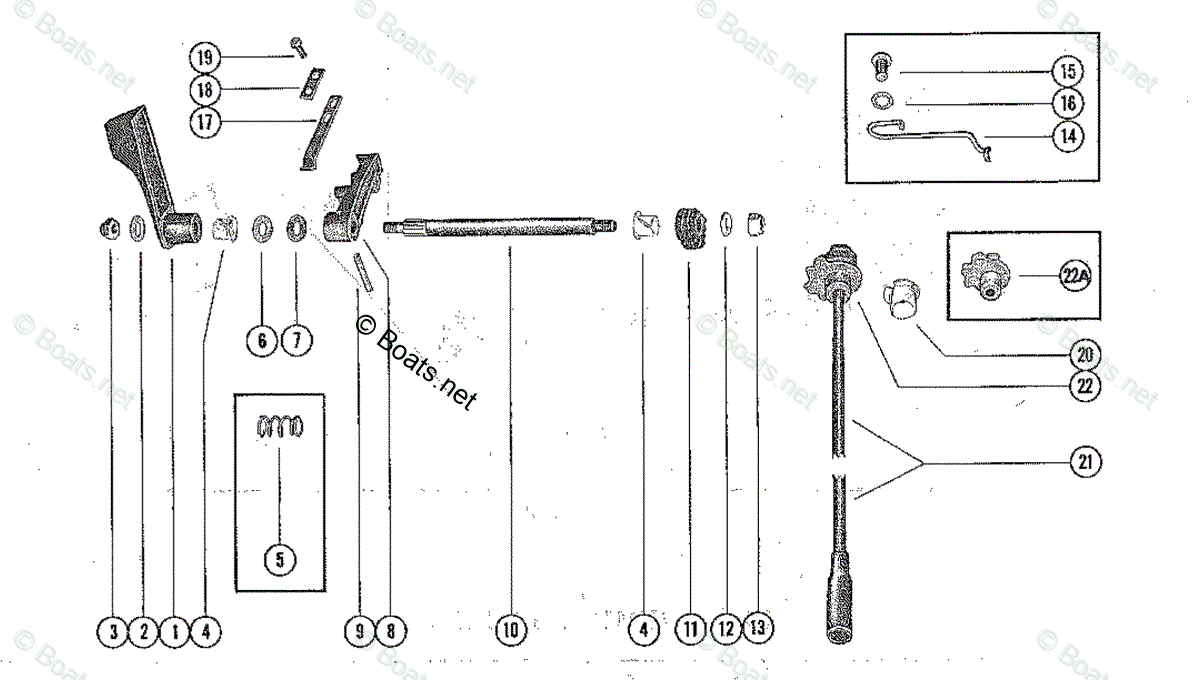

Shift Shaft

The shift shaft is a rotating shaft located within the lower unit of the outboard. It's connected to the shift linkage rods and levers. When the shift shaft rotates, it engages or disengages the gears inside the lower unit.

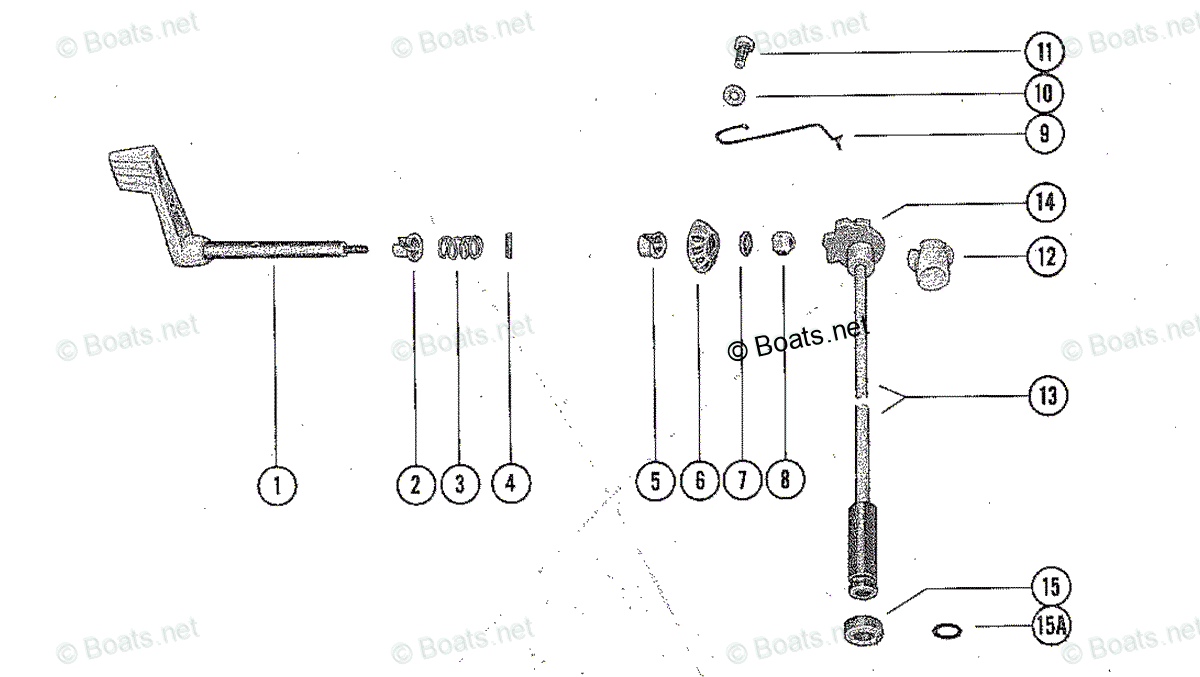

Shift Cam or Detent Mechanism

This mechanism is responsible for precisely positioning the shift shaft in the correct gear. It typically consists of a cam, detent ball, and spring. The detent ball locks into specific positions on the cam, corresponding to forward, neutral, or reverse. This ensures the gears are fully engaged and prevents slippage.

Gearcase (Lower Unit) Components

While not strictly part of the linkage itself, the components within the gearcase (forward gear, reverse gear, clutch dog) are integral to the overall shifting process. The shift linkage ultimately controls the clutch dog, which engages either the forward or reverse gear. Neutral occurs when the clutch dog is disengaged from both gears.

Functional Operation of the Shift Linkage

The entire shift linkage system operates sequentially to engage the appropriate gear. Here's a step-by-step explanation:

- Operator Input: The operator moves the shift control lever to the desired position (forward, neutral, or reverse).

- Cable Activation: The movement of the shift control lever pulls or pushes the shift cable.

- Linkage Translation: The motion of the shift cable is transferred to the shift linkage rods and levers on the engine. These components translate the linear cable movement into a rotational movement of the shift shaft.

- Shift Shaft Rotation: The shift shaft rotates, guided by the shift cam and detent mechanism, to the correct position for the selected gear.

- Gear Engagement: The rotation of the shift shaft moves the clutch dog within the gearcase, engaging either the forward or reverse gear (or neither for neutral).

- Propeller Rotation: With the gear engaged, the engine's power is transmitted through the gearcase to the propeller, causing it to rotate in the appropriate direction (forward or reverse).

Common Issues and Troubleshooting

Shift linkage problems can manifest in various ways, including difficulty shifting, grinding noises, or the inability to engage a specific gear. Here are some common issues and potential troubleshooting steps:

Cable Adjustment

Incorrect cable adjustment is a frequent cause of shifting problems. If the cable is too loose or too tight, it may not fully engage the gears. Proper cable adjustment ensures that the shift shaft reaches its correct positions for each gear.

Troubleshooting: Consult the Mercury outboard service manual for the specific cable adjustment procedure. This typically involves loosening the cable end fittings and adjusting the cable length until the shift lever positions correspond correctly to the gear engagement.

Worn or Damaged Cables

Over time, shift cables can become stretched, corroded, or damaged. This can lead to sluggish shifting or the inability to engage gears. Kinks or bends in the cable can also impede its movement.

Troubleshooting: Inspect the cable for visible signs of damage. If the cable feels stiff or binding, it should be replaced. A cable tester can be used to check for internal corrosion or damage.

Linkage Component Wear

The shift linkage rods, levers, and shift shaft bushings can wear over time due to friction and corrosion. This can create excessive play in the linkage, leading to inaccurate shifting.

Troubleshooting: Visually inspect the linkage components for wear or damage. Check for excessive play in the joints. Replace worn or damaged parts as needed.

Shift Cam and Detent Problems

The shift cam and detent mechanism can become worn or damaged, preventing the shift shaft from locking into the correct positions. This can cause gear slippage or difficulty shifting.

Troubleshooting: Inspect the shift cam and detent mechanism for wear or damage. The detent ball and spring should move freely. If the cam is worn or the detent mechanism is malfunctioning, it should be replaced.

Gearcase Issues

Although technically not part of the linkage, problems *within* the gearcase can *mimic* linkage problems. Damaged gears or a malfunctioning clutch dog can prevent proper gear engagement.

Troubleshooting: If you've ruled out linkage problems, inspect the gearcase. This often requires draining the gear oil and removing the gearcase for inspection. Look for worn or damaged gears, clutch dog issues, or excessive metal shavings in the oil. Gearcase repairs often require specialized tools and expertise.

Lubrication

Proper lubrication of the shift linkage components is essential for smooth operation and preventing corrosion. Lack of lubrication can lead to stiff shifting and accelerated wear.

Troubleshooting: Regularly lubricate the shift linkage components with a marine-grade grease. Pay particular attention to the pivot points on the linkage rods and levers. Refer to the Mercury outboard service manual for recommended lubrication points and intervals.

Importance of Proper Maintenance

Regular maintenance of the Mercury outboard shift linkage is critical for ensuring reliable and safe operation. Neglecting maintenance can lead to shifting problems, which can be inconvenient at best and dangerous at worst. Proper maintenance includes:

- Regularly inspecting the shift cable and linkage components for wear or damage.

- Lubricating the linkage components with a marine-grade grease.

- Adjusting the shift cable as needed to ensure proper gear engagement.

- Replacing worn or damaged components promptly.

By following these maintenance practices, you can extend the life of your shift linkage system and avoid costly repairs.

Conclusion

The Mercury outboard shift linkage is a complex yet vital system. A thorough understanding of its components, operation, and potential problems is key to diagnosing and resolving shifting issues. Proper maintenance, including lubrication and cable adjustment, is crucial for ensuring smooth and reliable gear engagement. Addressing these areas will contribute significantly to the overall performance and longevity of your outboard motor, ensuring a safe and enjoyable boating experience.