Replacing Stringers On Fiberglass Boat

Fiberglass boat stringer replacement is a significant structural repair often required due to water intrusion and subsequent rot. The following outlines the typical process.

Assessment and Preparation

The initial step involves a thorough inspection to determine the extent of the damage. This includes visual examination, sounding with a hammer or similar tool, and moisture meter readings. Moisture meters can indicate the presence of excessive moisture within the stringer core.

Documentation is critical. Create detailed sketches and take photographs of the existing stringer layout, dimensions, and tabbing schedule. This provides a reference for the new stringer placement and lamination schedule.

Removing Interior Components

Access to the stringers often requires removing interior components such as flooring, liners, fuel tanks, and other obstructions. Careful disconnection of wiring and plumbing is necessary. Label and store all removed items systematically.

Grinding and Core Removal

The fiberglass tabbing that secures the stringers to the hull and deck must be ground away. Use appropriate personal protective equipment (PPE), including a respirator, eye protection, and protective clothing. Feather the edges of the remaining fiberglass to create a smooth transition for the new laminate.

The deteriorated stringer core material must be removed. This can involve using chisels, scrapers, saws, or other appropriate tools. Take care not to damage the surrounding fiberglass hull.

Stringer Fabrication

New stringers can be fabricated from various materials, including marine-grade plywood, composite materials (such as fiberglass-reinforced foam), or solid fiberglass. Marine-grade plywood is commonly used but must be fully encapsulated in fiberglass to prevent future rot.

Plywood Stringer Construction

If using plywood, ensure it meets marine-grade standards (e.g., BS 1088). Cut the plywood to the dimensions documented earlier. Multiple layers of thinner plywood can be laminated together using epoxy resin to achieve the desired thickness and shape. Stagger the seams of the plywood layers for increased strength.

Composite Stringer Construction

Composite stringers offer advantages in terms of weight and resistance to rot. These stringers are typically constructed by laminating layers of fiberglass cloth and resin over a foam core. The foam core provides shape and support during the lamination process.

Stringer Shape and Dimensions

The new stringers should match the original stringer dimensions and shape as closely as possible. Use the original stringer remnants or the documentation created during the assessment phase as a guide. Ensure the stringers are properly shaped to conform to the hull contours.

Installation and Lamination

Prior to installing the new stringers, ensure the bonding surfaces on the hull are clean and free of debris. Grind the hull surface with coarse sandpaper (e.g., 36-grit) to create a mechanical bond for the new laminate.

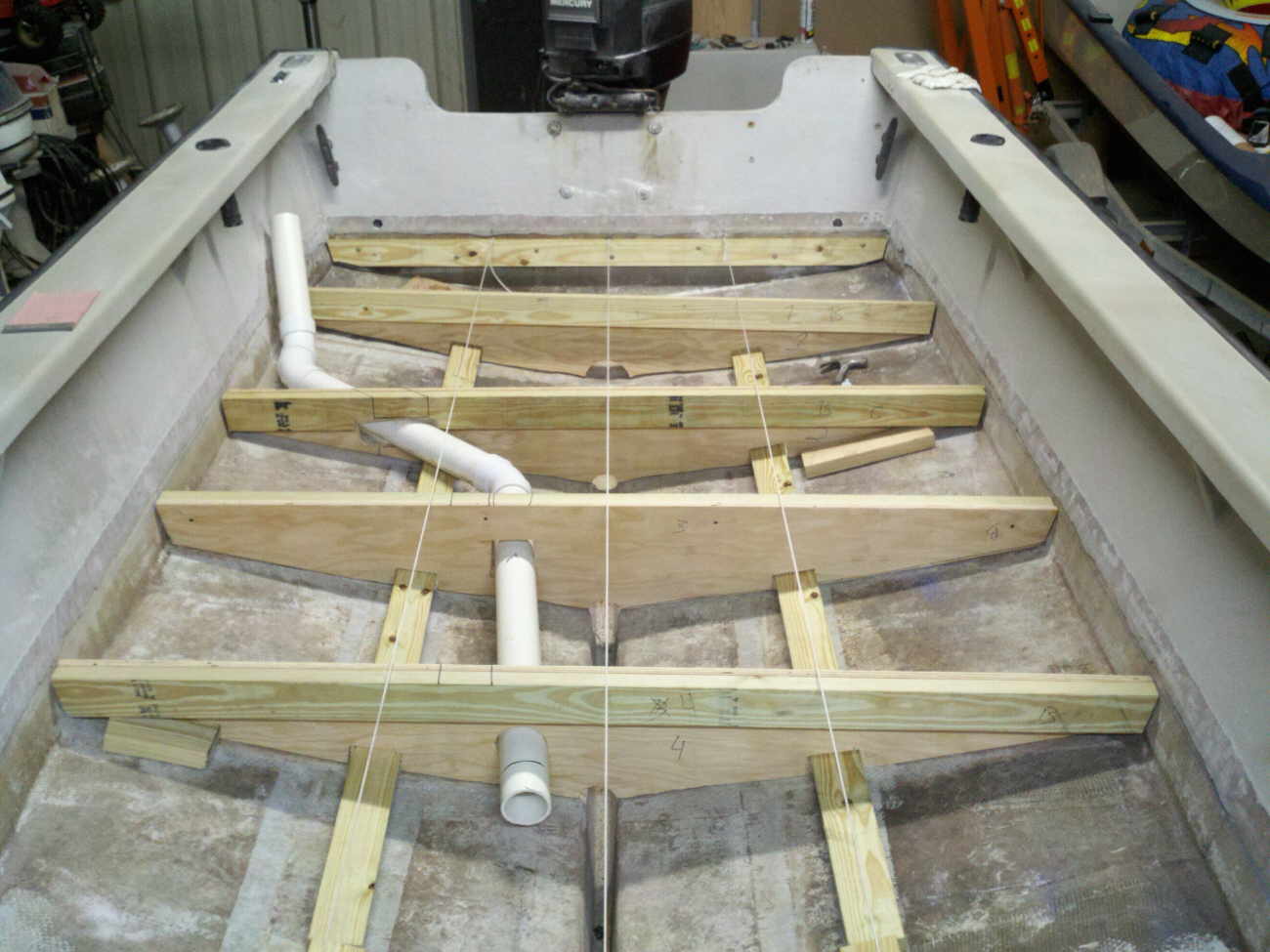

Stringer Placement

Position the new stringers in their original locations, using temporary supports to hold them in place. Verify alignment and ensure they are properly seated against the hull. Use shims if necessary to achieve a consistent fit.

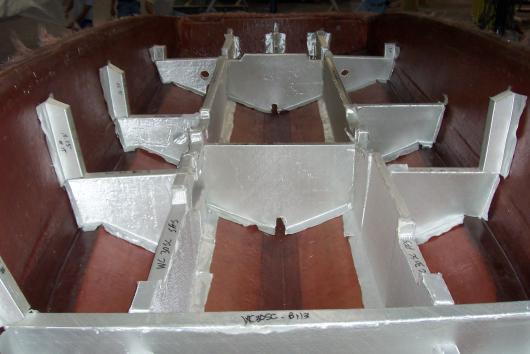

Tabbing

Tabbing is the process of laminating fiberglass cloth and resin to secure the stringers to the hull and deck. Use multiple layers of fiberglass cloth, overlapping each layer to create a strong bond. The width of the tabbing should be sufficient to distribute the load evenly.

For example, a typical tabbing schedule might involve three layers of fiberglass cloth, with each layer overlapping the previous layer by 2 inches. The first layer might be 4 inches wide, the second 8 inches wide, and the third 12 inches wide.

Wet-out the fiberglass cloth thoroughly with resin, using a brush or roller. Remove any air bubbles to ensure a strong bond. Overlap the tabbing onto the hull and stringer by a minimum of several inches. Stagger the seams of the fiberglass cloth layers for added strength.

Resin Selection

Epoxy resin is generally preferred for structural repairs due to its superior strength, water resistance, and bonding properties. Polyester resin can also be used, but it is typically less durable and more susceptible to water intrusion. Vinylester resin offers a compromise between epoxy and polyester, providing good strength and water resistance.

Lamination Schedule

The lamination schedule, which specifies the number of layers of fiberglass cloth and the type of resin used, should be determined based on the original construction and the expected loads. Consult with a marine surveyor or structural engineer for guidance on selecting an appropriate lamination schedule.

Finishing and Reassembly

Once the lamination has cured, grind any rough edges or imperfections. Apply a layer of gelcoat to protect the fiberglass and provide a smooth finish. Sand the gelcoat and polish to achieve the desired appearance.

Reinstalling Interior Components

Carefully reinstall all interior components that were removed during the preparation phase. Reconnect wiring and plumbing, ensuring all connections are secure. Test all systems to verify they are functioning properly.

Inspection

After completing the repair, conduct a thorough inspection to ensure the stringers are properly installed and the lamination is sound. Check for any signs of voids or delamination. A marine surveyor can provide an independent assessment of the repair.

Post-Repair Maintenance

Regularly inspect the stringers for any signs of water intrusion or damage. Address any issues promptly to prevent further deterioration. Ensure proper ventilation to minimize moisture buildup within the boat.

Apply a bilge coating to protect the interior of the hull from water damage. Keep the bilge clean and dry to prevent the growth of mold and mildew.

Key Takeaways

- Thorough assessment and documentation are paramount for a successful stringer replacement.

- Proper preparation of bonding surfaces is critical for a strong and durable repair.

- Use marine-grade materials and appropriate resins for optimal performance.

- A well-executed lamination schedule is essential for structural integrity.

- Regular maintenance and inspection will prolong the life of the repair.