Maintaining the sterility of medical supplies is paramount to patient safety. A cornerstone of ensuring this sterility lies in adhering to established standards for storage. The Association for the Advancement of Medical Instrumentation (AAMI) provides comprehensive guidelines that are widely recognized and implemented in healthcare facilities to safeguard the integrity of sterile items. This article will elucidate these AAMI standards for storage of sterile supplies in a step-by-step manner.

Understanding Sterility Maintenance

Before delving into the specific storage guidelines, it's crucial to define what constitutes a sterile item and the importance of maintaining its sterility. A sterile item is defined as one that is free from all living microorganisms, including bacteria, viruses, fungi, and spores. Maintaining this sterility is essential to prevent healthcare-associated infections (HAIs) which can lead to increased morbidity, mortality, and healthcare costs.

The concept of event-related sterility is central to AAMI's guidelines. This concept acknowledges that the sterility of an item is maintained unless a specific event compromises the packaging or the storage environment. Instead of focusing on expiration dates alone (although expiration dates are still important), event-related sterility emphasizes proper handling, storage, and inspection of sterile items.

Key AAMI Standards for Sterile Storage

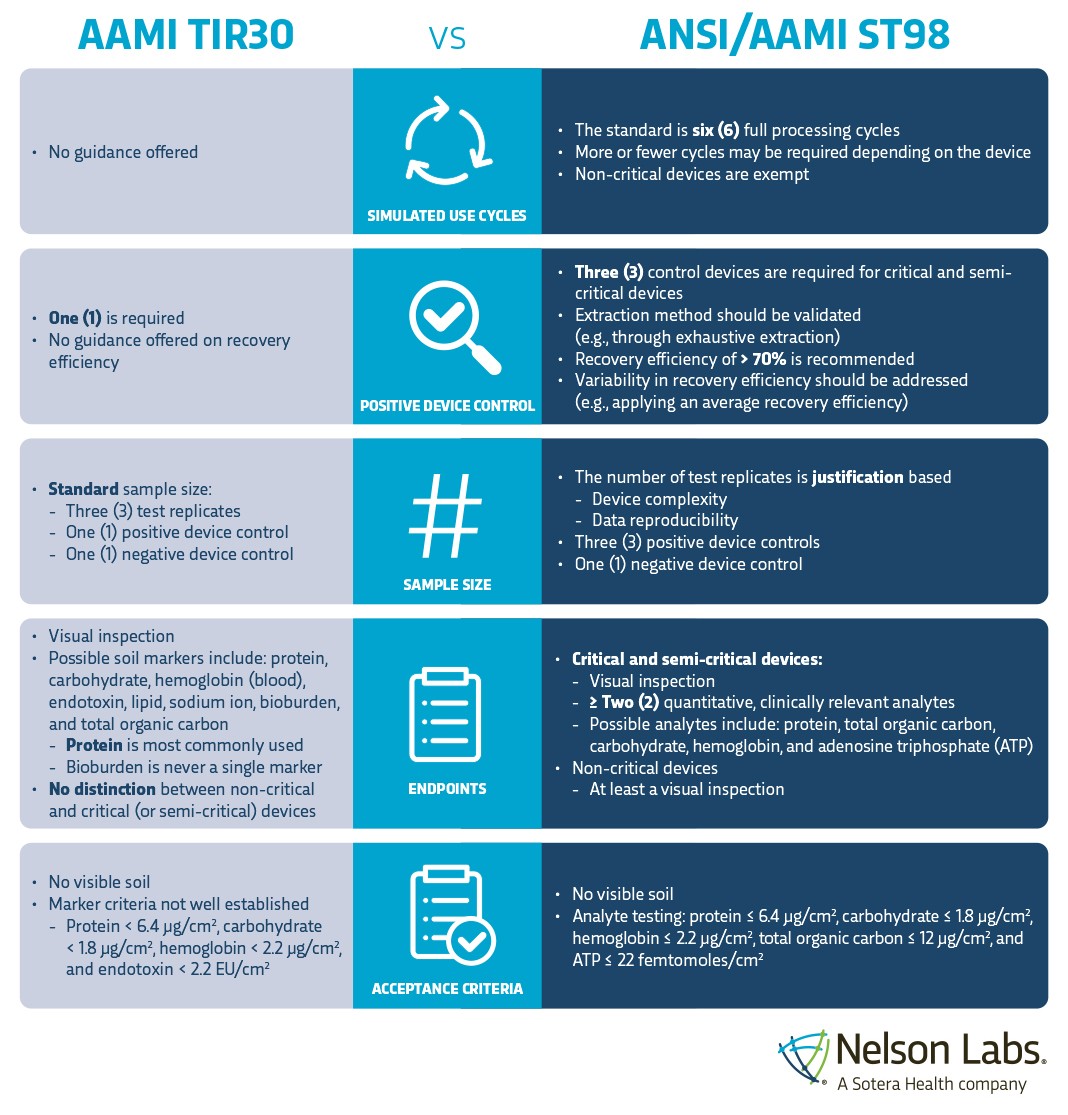

AAMI's recommendations are outlined in several documents, most notably ANSI/AAMI ST79: Comprehensive guide to steam sterilization and sterility assurance in health care facilities. These recommendations address various aspects of sterile storage, including environmental controls, storage location, handling practices, and inventory management.

1. Environmental Controls: Temperature and Humidity

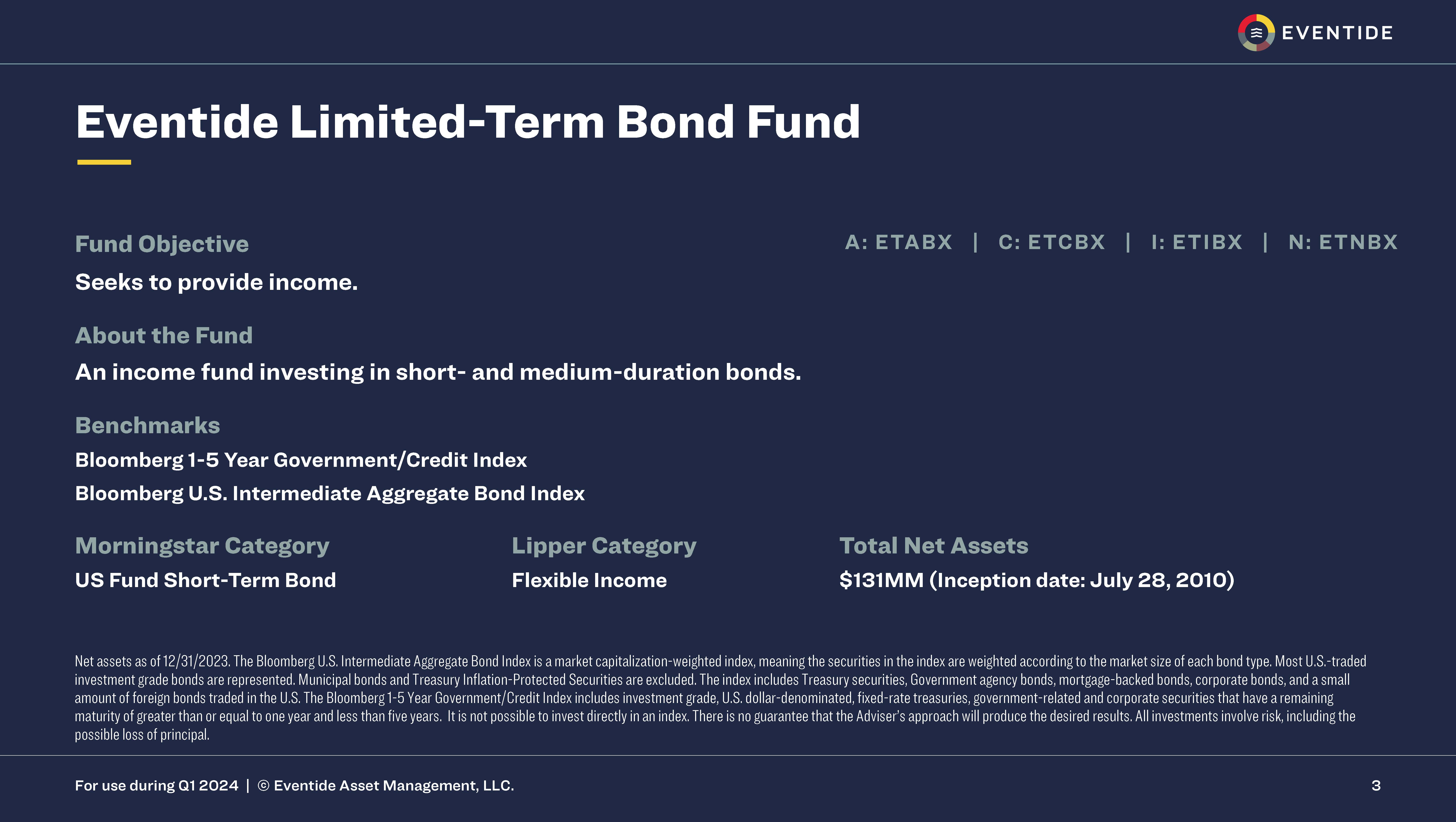

Controlling the temperature and humidity of the storage area is fundamental. AAMI recommends maintaining temperature and humidity levels within a specific range to prevent the growth of microorganisms and degradation of packaging materials. Generally, a temperature range of 64°F to 75°F (18°C to 24°C) and a relative humidity of 30% to 60% are recommended.

To achieve these levels, the storage area should be equipped with a reliable HVAC (Heating, Ventilation, and Air Conditioning) system. Regular monitoring of temperature and humidity using calibrated instruments is essential. Documentation of these readings should be maintained to demonstrate compliance with AAMI standards. Any deviations from the recommended range should be promptly investigated and corrective actions implemented.

For example, if humidity levels consistently exceed 60%, consider using dehumidifiers to lower the moisture content. Conversely, if humidity levels are consistently below 30%, humidifiers may be necessary. Temperature control is generally managed through the HVAC system, ensuring adequate airflow and insulation.

2. Storage Location and Design

The physical location and design of the storage area play a significant role in maintaining sterility. The storage area should be a dedicated space, separate from areas where soiled or contaminated items are handled. This prevents cross-contamination and ensures a clean environment.

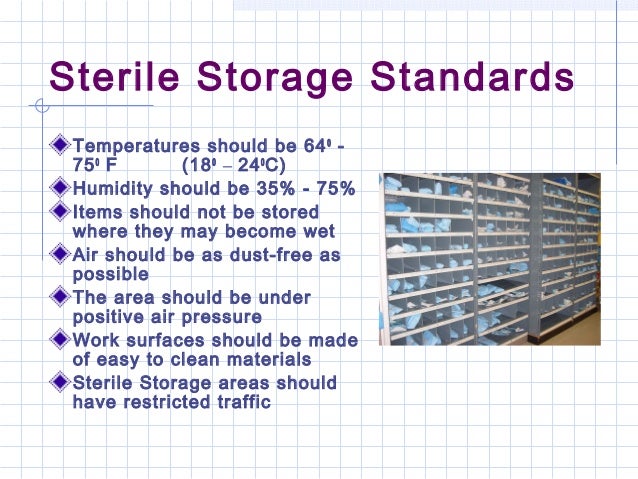

Shelving should be constructed of non-shedding materials such as stainless steel or epoxy-coated wire. Wooden shelves are generally discouraged as they can harbor microorganisms and are difficult to clean. Shelves should be positioned at least 8-10 inches (20-25 cm) off the floor to facilitate cleaning and prevent damage from spills or water accumulation. Similarly, shelves should be at least 18 inches (46 cm) from the ceiling to allow for adequate air circulation.

Adequate spacing between shelves is crucial for air circulation and to allow for easy handling of sterile items. Items should not be tightly packed together, as this can impede airflow and increase the risk of damage to packaging. Aisles should be wide enough to allow for easy access and movement of personnel and equipment.

Proper storage location ensures minimized risk of contamination and easy accessibility.

3. Handling Practices

Proper handling of sterile items is critical to preventing contamination. Personnel handling sterile supplies should be trained in aseptic techniques and understand the importance of maintaining sterility. Hands should be thoroughly washed or sanitized before handling sterile items.

When retrieving items from storage, care should be taken to avoid damaging the packaging. Items should be lifted and not dragged across shelves. Visual inspection of the packaging should be performed before use. Any item with compromised packaging (e.g., tears, punctures, water stains) should be considered contaminated and reprocessed.

The "first in, first out (FIFO)" principle should be strictly followed to ensure that items are used before their expiration dates. This involves rotating stock regularly and placing newly sterilized items behind older items. This practice minimizes the risk of using expired items and ensures that all items are used within their designated shelf life.

Consider this scenario: A box of sterile gloves is placed at the back of the shelf after a new shipment arrives. After one month, a nurse grabs a new box of gloves without verifying if it has a later expiration date and takes it for surgery. If it does, the old box of gloves, although placed in the front, will expire unnoticed. To avoid this, regularly check the expiry dates and rotate stock.

4. Packaging Integrity and Inspection

The integrity of the packaging is a direct indicator of the sterility of the contents. Sterile items must be packaged in materials that are compatible with the sterilization process and provide a barrier against microbial penetration. Common packaging materials include sterilization wraps, pouches, and rigid containers.

Prior to storing sterile items, a thorough visual inspection of the packaging should be conducted. Look for any signs of damage, such as tears, punctures, water stains, or broken seals. Also, check the integrity of the chemical indicators used to verify that the sterilization process was effective. If the chemical indicator has not changed color appropriately, the item should be considered non-sterile.

Any item with compromised packaging should be immediately removed from sterile storage and reprocessed. It is imperative to have a clear policy and procedure for handling damaged or questionable items.

5. Inventory Management and Tracking

Effective inventory management is essential for maintaining an adequate supply of sterile items and preventing stockouts. A computerized inventory management system can greatly facilitate this process by tracking inventory levels, expiration dates, and usage patterns.

Regular cycle counts should be performed to verify the accuracy of the inventory system. This involves physically counting the items in storage and comparing the results to the inventory records. Discrepancies should be promptly investigated and resolved.

In addition to tracking inventory levels, it is also important to track the sterilization history of each item. This includes the date of sterilization, the sterilizer used, and the results of biological monitoring. This information can be valuable in the event of a sterilization failure or recall.

Practical Advice and Insights

Implementing AAMI standards for sterile storage requires a comprehensive approach involving all healthcare personnel. Regular training and education are essential to ensure that staff members understand the importance of sterile storage practices and are competent in performing their duties.

Here are some practical tips for everyday life, even outside of a healthcare setting:

- Visual Inspection: Before using any pre-packaged sterile item, such as contact lens solutions or wound dressings, always visually inspect the packaging for any signs of damage.

- Proper Storage: Store these items in a clean, dry place away from direct sunlight and extreme temperatures.

- Expiration Dates: Be mindful of expiration dates and discard any items that have expired.

- Hand Hygiene: Always wash your hands thoroughly before handling sterile items.

Adherence to AAMI standards for sterile storage is not merely a regulatory requirement; it is a fundamental aspect of patient safety. By implementing these guidelines, healthcare facilities can significantly reduce the risk of healthcare-associated infections and improve patient outcomes. Continuous monitoring, evaluation, and improvement of sterile storage practices are essential for maintaining a safe and effective healthcare environment.

2008.jpg)

+other+standards+into.jpg)

.jpg)

_page_01.jpg?sfvrsn=3b55cf0b_2)