Brad Nails vs. Finish Nails: Dissecting the Differences

In woodworking and construction, the terms "brad nails" and "finish nails" are often used, sometimes interchangeably, leading to confusion. While both serve the purpose of fastening materials, they possess distinct characteristics that make them suitable for different applications. This article provides a factual comparison to clarify their differences and appropriate uses.

Defining Brad Nails

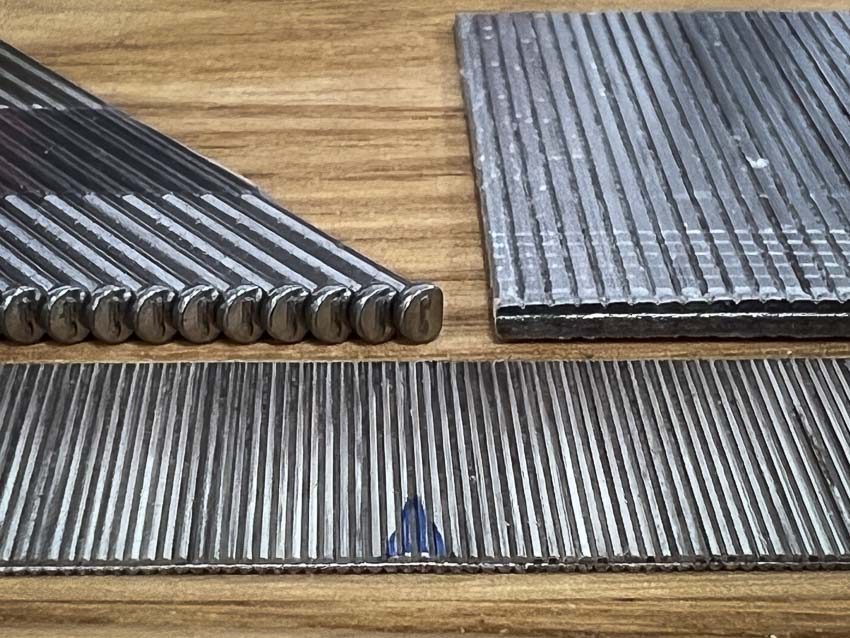

Brad nails are slender nails typically ranging in gauge from 18 to 21. The gauge number inversely correlates with the nail's diameter; thus, an 18-gauge brad nail is thicker than a 21-gauge one. They are designed for delicate projects where minimal visibility of the nail head is desired. Their small diameter reduces the risk of splitting wood, particularly in brittle materials or near edges.

Brad nailers, the tools used to drive brad nails, are pneumatically powered or electric. They efficiently and consistently embed the nail with minimal surface disruption. Common lengths for brad nails vary from ½ inch to 2 inches.

Understanding Finish Nails

Finish nails are thicker than brad nails, generally ranging from 15 to 16 gauge. This increased thickness provides greater holding power, making them appropriate for more substantial fastening tasks. They are designed with a small, slightly countersunk head that can be easily concealed with wood filler or paint.

Like brad nailers, finish nailers are typically pneumatic or electric. Due to the larger gauge, finish nailers offer a more robust driving force. Finish nail lengths commonly range from 1 inch to 3 ½ inches.

A Detailed Comparison

To fully understand the distinctions, we need to analyze key attributes:

Gauge and Diameter

This is the most critical difference. Brad nails, being 18-21 gauge, are significantly thinner than finish nails (15-16 gauge). This difference in diameter dictates their respective strengths and applications.

Thinner gauge equates to less holding power, while thicker gauge offers greater strength.

Head Size and Shape

Both brad and finish nails have small heads designed to be inconspicuous. However, finish nails often have a slightly larger head and a more pronounced countersinking capability compared to brad nails. This allows for easier filling and a smoother finish.

Holding Power

Finish nails, owing to their larger diameter, provide significantly greater holding power than brad nails. This makes them suitable for applications requiring a stronger, more secure bond.

Wood Splitting

Brad nails, with their slender profile, are less likely to split wood, especially near edges or in delicate materials. Finish nails, due to their increased thickness, present a higher risk of splitting in certain circumstances.

Visibility

Both nails are designed for minimal visibility. However, brad nails generally leave a smaller hole, making them ideal when concealing the fastener is paramount. The larger head of the finish nail, while designed to be filled, might require more effort for complete concealment.

Applications

Understanding the differences allows for correct application selection:

Brad Nail Applications

Brad nails are well-suited for:

- Trim and Molding: Attaching delicate trim pieces where minimal damage is crucial.

- Crafts and Hobbies: Assembling lightweight projects where strength isn't a primary concern.

- Picture Frames: Securing the corners of picture frames without causing visible damage.

- Cabinet Assembly (Temporary): Holding cabinet parts together during glue drying.

- Small Woodworking Projects: Constructing small boxes or decorative items.

Finish Nail Applications

Finish nails are suitable for:

- Baseboards and Crown Molding: Installing larger trim pieces that require a stronger hold.

- Door and Window Casings: Securing door and window frames.

- Furniture Construction: Assembling furniture components where a robust connection is needed.

- Cabinet Installation: Attaching cabinets to walls.

- Hardwood Flooring (Secret Nailing): Securing hardwood flooring through the tongue at an angle.

Addressing Common Misconceptions

A common misconception is that one type of nail can universally replace the other. While in some situations, a finish nail could be used where a brad nail is called for (although it increases splitting risk), the reverse is rarely true. A brad nail simply lacks the holding power required for many finish nail applications.

Another misconception involves thinking the nailer determines the application. While the nailer is the tool, the nail itself is the deciding factor. You cannot use a finish nail in a brad nailer and vice versa. The nailer is designed specifically for the gauge and length of nail it's intended to use.

Selecting the Right Nail for the Job

Choosing between brad and finish nails depends on project requirements. Consider these factors:

- Material Thickness and Density: Thicker, denser materials generally require finish nails.

- Required Holding Power: Projects needing a strong, secure bond benefit from finish nails.

- Desired Finish: If minimal visibility and minimal filling are priorities, brad nails are ideal.

- Potential for Splitting: Delicate woods or close-to-the-edge nailing favor brad nails.

- Cosmetic Considerations: For projects where the fastener will be visible, the smaller hole left by a brad nail might be preferable.

Conclusion: Key Takeaways

Brad nails and finish nails, while both used for fastening, are not interchangeable. Here's a concise summary:

- Gauge is the Key Difference: Brad nails are thinner (18-21 gauge) than finish nails (15-16 gauge).

- Holding Power: Finish nails offer superior holding power.

- Splitting Risk: Brad nails are less likely to split wood.

- Applications: Brad nails for delicate trim, crafts; finish nails for baseboards, furniture.

- Nailer Compatibility: Nailers are designed for specific nail gauges and lengths. Using the wrong nail can damage the tool and be unsafe.

By understanding these distinctions, woodworkers and builders can select the appropriate nail for their specific project, ensuring both structural integrity and a professional finish. Using the right nail will lead to a stronger, cleaner, more durable final product.