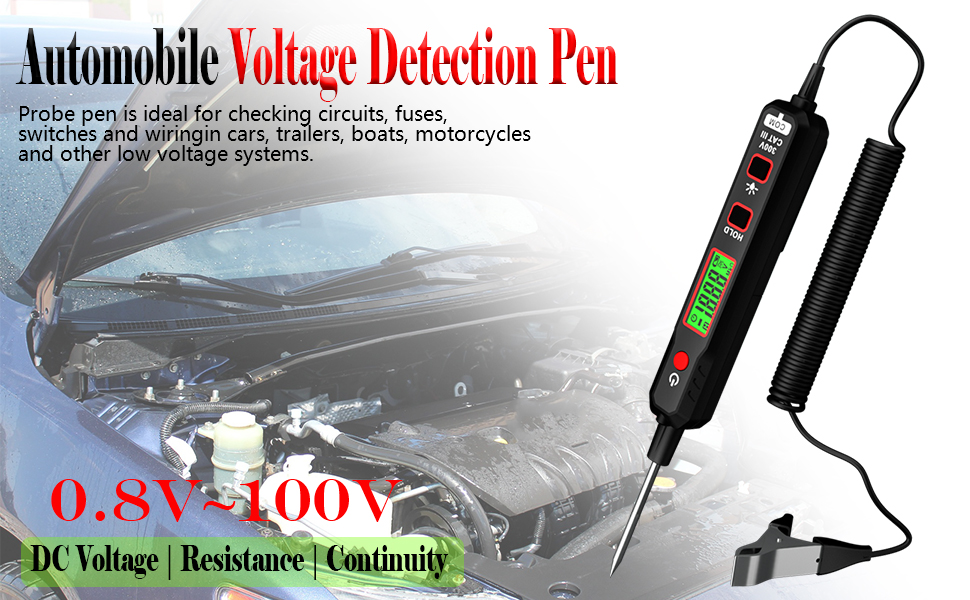

An automotive non-contact DC voltage tester is a diagnostic tool designed to detect the presence of direct current (DC) voltage in electrical circuits without requiring physical contact with the conductor. This method employs electromagnetic field sensing technology to identify voltage presence, simplifying troubleshooting and enhancing safety during automotive electrical system diagnostics.

Understanding the Principles of Operation

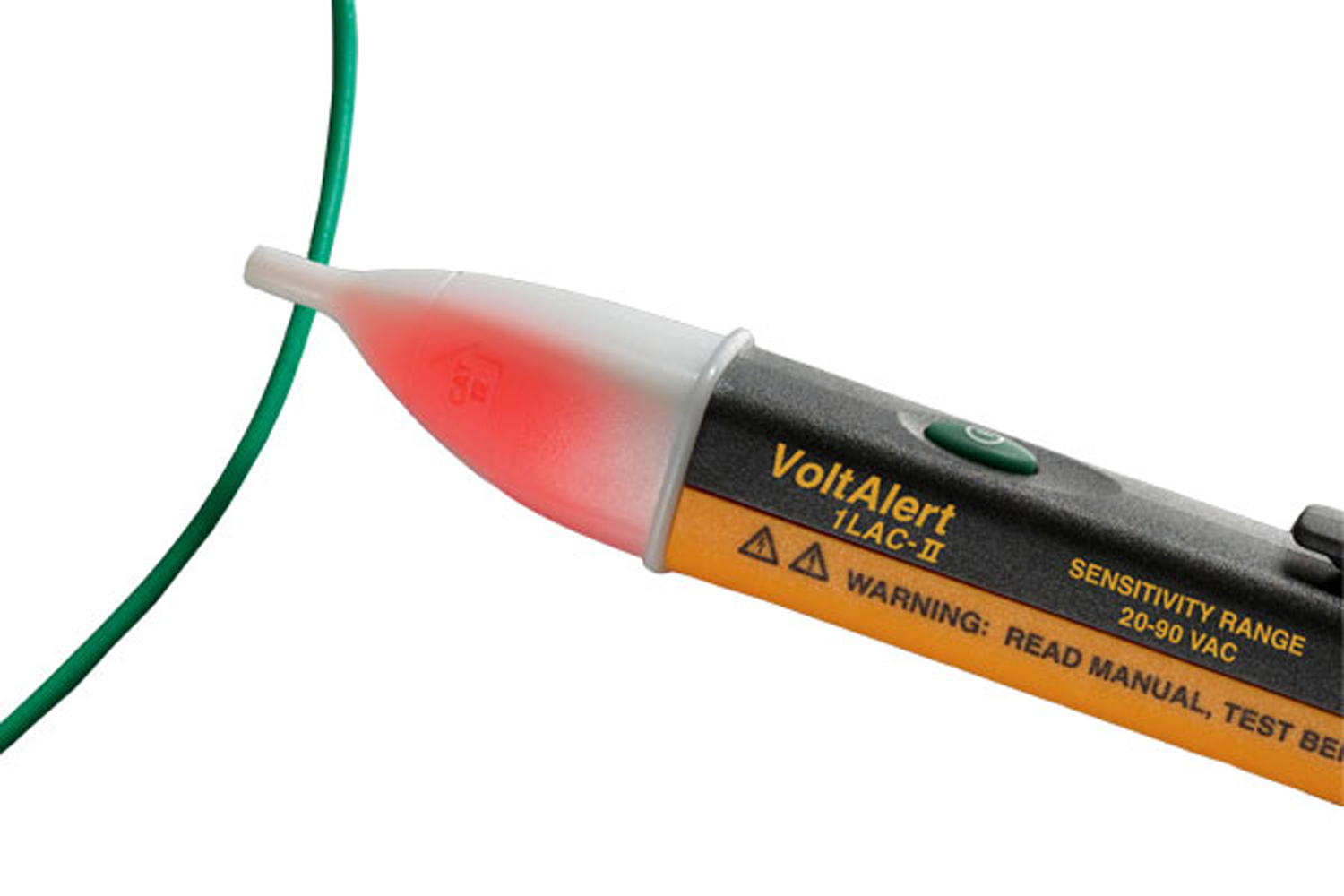

The functionality of a non-contact DC voltage tester relies on the detection of the electric field generated by a DC voltage. A DC voltage establishes a static electric field surrounding the conductor. The tester houses a sensitive sensor capable of detecting alterations in this field. When the device is placed near a wire carrying DC voltage, the sensor detects the electric field, and the tester indicates the presence of voltage, typically through an audible beep, a visual LED indicator, or a display screen showing the voltage level.

Key Components and Their Functions

The typical components of a non-contact DC voltage tester include:

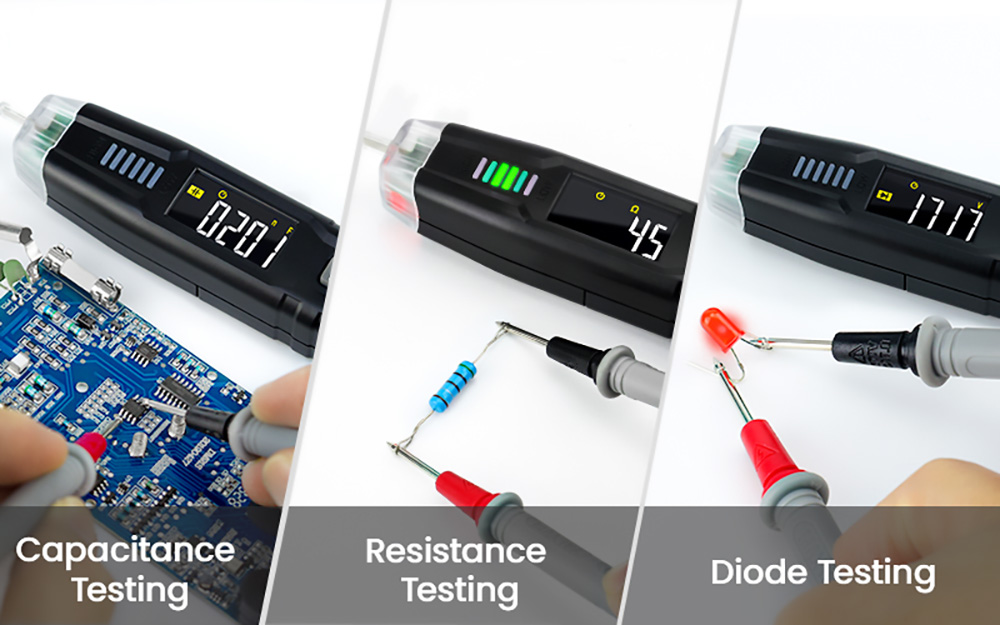

- Sensor: The core element responsible for detecting the electric field. Its sensitivity dictates the tester's ability to detect voltage from a distance.

- Signal Processing Circuitry: This circuitry amplifies and filters the signal received from the sensor, differentiating between genuine voltage readings and extraneous noise.

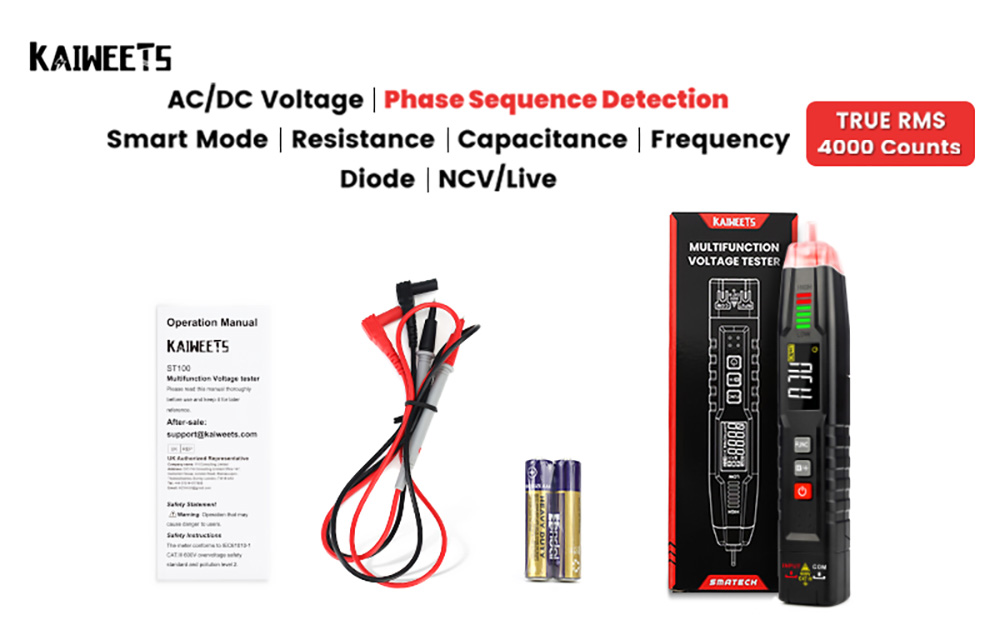

- Indicator: The means by which the tester alerts the user to the presence of voltage. This could be an LED, an audible buzzer, or an LCD screen displaying the voltage level.

- Power Source: Typically batteries (e.g., AAA, AA), which supply the necessary power for the sensor and signal processing circuitry.

- Housing: Provides physical protection for the internal components and a safe grip for the user.

Using a Non-Contact DC Voltage Tester: A Step-by-Step Guide

To effectively use a non-contact DC voltage tester, adhere to the following procedure:

- Safety First: Before commencing any electrical testing, ensure the vehicle is parked on a level surface, the parking brake is engaged, and the ignition is switched off. Disconnecting the negative battery terminal is advisable for added safety, though a non-contact tester minimizes direct contact risks.

- Power On the Tester: Insert batteries if required and activate the power switch. Some testers feature a self-test function; activate it to verify proper functionality.

- Select the Appropriate Voltage Range: Many testers offer adjustable sensitivity or voltage ranges. Select the appropriate range for the voltage level you anticipate detecting. Starting with the highest range and gradually decreasing it ensures accurate readings and protects the device from potential damage due to unexpectedly high voltage.

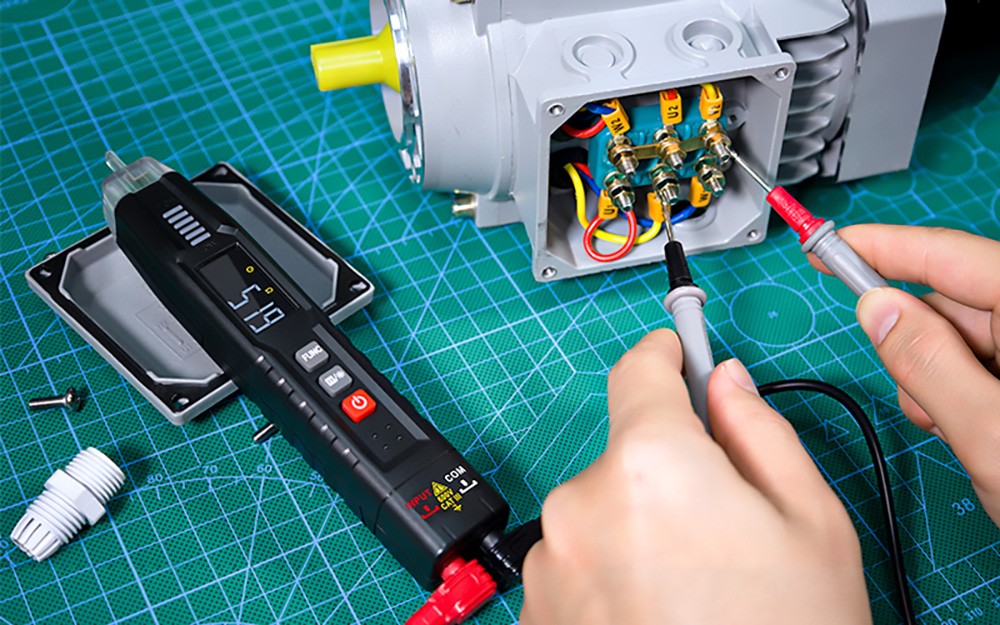

- Approach the Circuit: Hold the tip of the tester near the wire or component you wish to test. Maintain a distance of approximately 1/4 to 1/2 inch (6 to 12 mm). Ensure that your fingers do not touch any exposed metal on the tester or the circuit being tested.

- Observe the Indication: Monitor the indicator for any signs of voltage presence. A beep, a lit LED, or a voltage reading on the LCD screen indicates that DC voltage is present.

- Interpretation of Results: If the tester indicates voltage, it confirms that the circuit is active. If no voltage is detected, it suggests that the circuit is either de-energized or there is a fault in the wiring or component.

- Verification: To ensure accuracy, repeat the test at multiple points along the circuit. If possible, compare the readings with a known good circuit to confirm the accuracy of the results.

- Power Off and Storage: After completing the testing, power off the tester and store it in a safe, dry place. Remove the batteries if the tester will not be used for an extended period.

Advantages of Non-Contact DC Voltage Testers

Non-contact DC voltage testers offer several advantages over traditional contact-based multimeters, especially in automotive applications:

- Safety: Reduced risk of electric shock as there is no need to make direct contact with live wires.

- Speed and Convenience: Faster testing process, especially useful for quickly identifying live circuits.

- Accessibility: Ability to test wires that are insulated or difficult to reach with multimeter probes.

- Non-Invasive Testing: Minimizes the risk of damaging insulation or creating shorts during testing.

Limitations and Precautions

Despite their advantages, non-contact DC voltage testers have limitations:

- Accuracy: Generally less accurate than direct contact multimeters, especially in noisy electrical environments.

- Sensitivity: Susceptible to interference from other electrical devices and electromagnetic fields. Nearby AC sources can cause false readings.

- Detection Range: Limited to detecting voltage within a certain proximity to the wire. Deeply buried or heavily shielded wires may not be detectable.

- Environmental Factors: Environmental conditions such as humidity and temperature can affect the tester's performance.

When using a non-contact DC voltage tester, observe the following precautions:

- Verify Tester Functionality: Always test the tester on a known live circuit before using it on an unknown circuit.

- Use Proper Grounding: Ensure the vehicle's electrical system is properly grounded to prevent inaccurate readings.

- Avoid Proximity to Other Electrical Devices: Keep the tester away from other electrical devices and sources of electromagnetic interference during testing.

- Read the User Manual: Always refer to the manufacturer's instructions for specific usage guidelines and safety precautions.

- Do not rely solely on the tester: In critical applications, verify the results with a direct contact multimeter.

Applications in Automotive Diagnostics

Non-contact DC voltage testers are particularly useful in automotive diagnostics for:

- Identifying blown fuses: Quickly checking for voltage at the fuse terminals.

- Troubleshooting wiring harnesses: Locating breaks or shorts in wiring without damaging the insulation.

- Verifying circuit continuity: Checking for voltage at various points in a circuit to ensure proper signal flow.

- Testing relays and switches: Confirming the presence of voltage at the relay or switch terminals.

- Diagnosing sensor failures: Checking for voltage at sensor inputs and outputs.

Practical Advice for Everyday Use

Here are some practical insights for using non-contact DC voltage testers in your daily life:

"When working on automotive electrical systems, always remember that safety is paramount. Even though a non-contact tester reduces the risk of electric shock, it is still essential to disconnect the battery whenever possible.

"To ensure accurate readings, avoid testing in areas with high electromagnetic interference, such as near electric motors or transformers. Move the vehicle or the tester to a less noisy environment."

"Regularly check the batteries in your tester. Low batteries can lead to inaccurate readings or complete failure of the device."

By understanding the principles of operation, following the proper usage procedures, and adhering to safety precautions, you can effectively utilize a non-contact DC voltage tester to simplify automotive electrical diagnostics and enhance your safety.