Coats & Clark Machine Embroidery Thread: A Detailed Overview

Coats & Clark, a name synonymous with sewing and crafting, offers a range of machine embroidery threads designed for both hobbyists and professionals. Understanding the characteristics and applications of their embroidery threads is crucial for achieving high-quality and durable results.

Thread Composition and Varieties

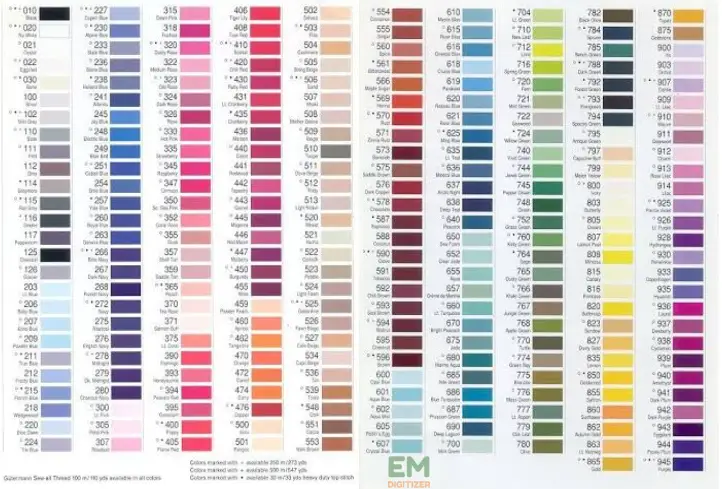

Coats & Clark primarily offers machine embroidery threads in two main compositions: polyester and rayon. Each material offers distinct advantages and is suitable for different applications.

Polyester Embroidery Thread

Polyester thread is known for its strength, durability, and colorfastness. It is resistant to fading, shrinking, and abrasion, making it an excellent choice for items that will be frequently washed or exposed to sunlight. Common applications include:

- Children's wear

- Outdoor apparel

- Home décor items (pillows, blankets)

- Commercial embroidery

Coats & Clark polyester embroidery threads are typically available in a wide array of colors and weights, allowing for versatility in design. The thread’s inherent strength makes it ideal for intricate designs and dense stitch patterns.

Rayon Embroidery Thread

Rayon thread is prized for its lustrous sheen and soft hand. It provides a more delicate and elegant appearance compared to polyester. However, it is less durable and more susceptible to fading and abrasion. Rayon thread is best suited for:

- Decorative embroidery

- Heirloom projects

- Items with minimal washing

- Applications where a luxurious finish is desired

Coats & Clark rayon embroidery threads are generally available in vibrant colors and offer exceptional stitch definition. Due to its delicate nature, it is often recommended to use a stabilizer to prevent stretching or puckering during the embroidery process.

Thread Weight and Needle Selection

Thread weight plays a crucial role in determining the appropriate needle size and overall appearance of the embroidery. Coats & Clark embroidery threads are typically available in weights ranging from 40 wt to 50 wt.

40 Weight Thread

40 weight thread is a common choice for machine embroidery. It provides good coverage and is suitable for a wide range of fabrics and designs. It is compatible with needle sizes ranging from 75/11 to 80/12.

50 Weight Thread

50 weight thread is finer than 40 weight thread and is often used for delicate designs and fine lettering. It requires a smaller needle, typically sizes 60/8 to 70/10. Using a finer thread can reduce bulk and improve stitch definition.

Choosing the correct needle size is essential for preventing thread breakage, skipped stitches, and fabric damage. Consult the Coats & Clark thread packaging for specific needle recommendations.

Proper Thread Tension and Machine Settings

Achieving optimal embroidery results depends heavily on proper thread tension and machine settings. Incorrect tension can lead to various issues, including:

- Looped stitches

- Bird's nests on the underside of the fabric

- Thread breakage

- Poor stitch definition

Coats & Clark recommends testing the thread tension on a scrap piece of fabric before embarking on the final project. Adjust the tension according to the machine manufacturer’s instructions. Generally, the top thread tension should be slightly tighter than the bobbin thread tension.

Additionally, consider the following machine settings:

- Stitch Density: Adjust the stitch density based on the fabric and design complexity. Higher stitch density provides better coverage but can also increase the risk of puckering.

- Embroidery Speed: Reduce the embroidery speed when working with delicate fabrics or intricate designs. This can help prevent thread breakage and improve stitch quality.

- Stabilizer Selection: Choose an appropriate stabilizer based on the fabric type and design density. Stabilizers provide support and prevent the fabric from stretching or distorting during the embroidery process.

Storage and Handling

Proper storage and handling of Coats & Clark embroidery thread are essential for maintaining its quality and preventing damage. Consider the following tips:

- Store threads in a cool, dry place away from direct sunlight.

- Protect threads from dust and moisture.

- Use thread racks or organizers to prevent tangling and breakage.

- Avoid exposing threads to extreme temperatures or humidity.

Before using a spool of thread, inspect it for any signs of damage or deterioration. Discard any thread that appears brittle, faded, or otherwise compromised.

Troubleshooting Common Issues

Despite careful planning and execution, embroidery enthusiasts may encounter occasional issues. Here are some common problems and potential solutions:

Thread Breakage

Thread breakage can be caused by various factors, including:

- Incorrect needle size

- Improper thread tension

- Damaged or worn needle

- Poor quality thread

- Excessive embroidery speed

To resolve thread breakage, try the following:

“Replace the needle, adjust the thread tension, reduce the embroidery speed, and ensure that the thread is properly threaded through the machine.”

Skipped Stitches

Skipped stitches occur when the needle fails to catch the bobbin thread, resulting in incomplete stitches. Potential causes include:

- Incorrect needle size

- Bent or damaged needle

- Improper needle insertion

- Incorrect thread tension

- Bobbin thread issues

To address skipped stitches, consider the following:

“Replace the needle, ensure that the needle is properly inserted, adjust the thread tension, and check the bobbin thread for proper winding and tension.”

Puckering

Puckering occurs when the fabric bunches up around the embroidery design. This can be caused by:

- Excessive stitch density

- Inadequate stabilization

- Improper thread tension

- Fabric stretching during embroidery

To minimize puckering, try the following:

“Reduce the stitch density, use a heavier stabilizer, adjust the thread tension, and avoid stretching the fabric during embroidery.”

Conclusion: Key Takeaways

Coats & Clark machine embroidery threads offer a reliable option for a wide range of embroidery projects. Choosing the appropriate thread composition (polyester or rayon), weight, and needle size is crucial for achieving optimal results. Proper thread tension, machine settings, and storage practices are also essential for preventing common issues such as thread breakage, skipped stitches, and puckering.

Key considerations when using Coats & Clark embroidery thread:

- Material Selection: Choose polyester for durability and rayon for a lustrous finish.

- Weight and Needle: Match the thread weight to the appropriate needle size.

- Tension Adjustment: Fine-tune thread tension for balanced stitches.

- Stabilization: Use adequate stabilizers to prevent fabric distortion.

- Storage Practices: Store thread properly to maintain its quality.

By following these guidelines, embroidery enthusiasts can confidently utilize Coats & Clark machine embroidery threads to create beautiful and long-lasting projects.