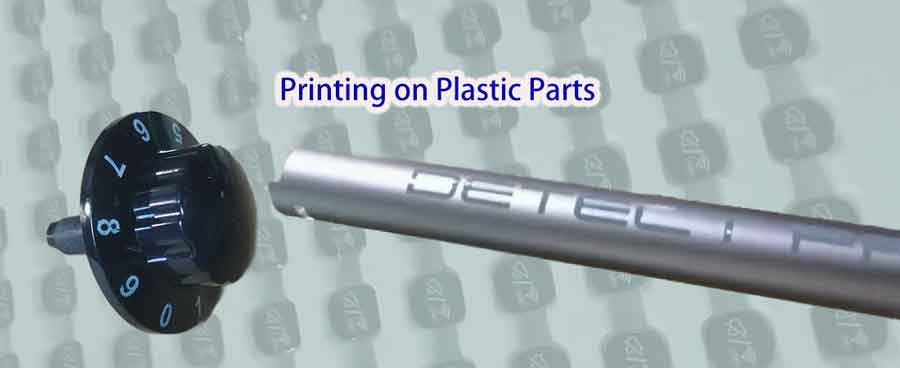

Alright, gather 'round, folks! Let me tell you about something incredibly fascinating... and, dare I say, surprisingly cool: digital inkjet printing on plastic parts. I know, I know, it doesn't exactly scream "party," but trust me, stick with me, it gets... at least mildly amusing. Think of it as the nerdy cousin of screen printing, but with way better dance moves (metaphorically, of course. Unless you're printing on dancing robots. Then, maybe literally).

What in the Plastic Fantastic is Inkjet Printing?

Okay, before we get too deep into the plastic fantastic, let's break down what inkjet printing actually is. Imagine your home printer, but instead of printing on paper, it's printing on, well, plastic! And instead of printing your questionable online shopping receipts, it's printing logos on car parts, serial numbers on medical devices, or even, if you're feeling particularly adventurous, incredibly detailed images of cats wearing tiny hats. The possibilities are almost endless (almost, I mean, you probably can't print a working time machine... yet!).

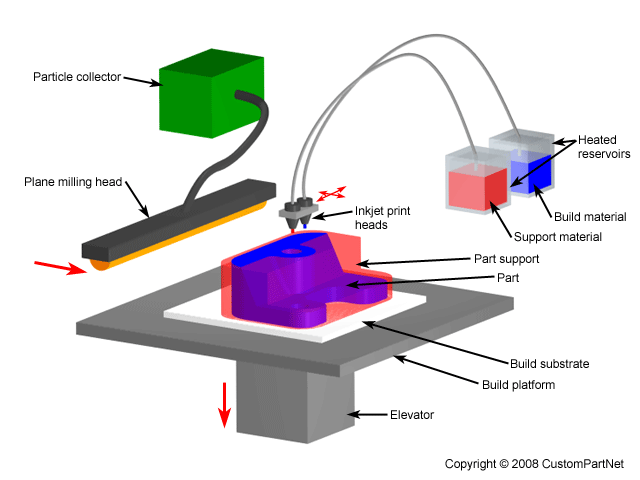

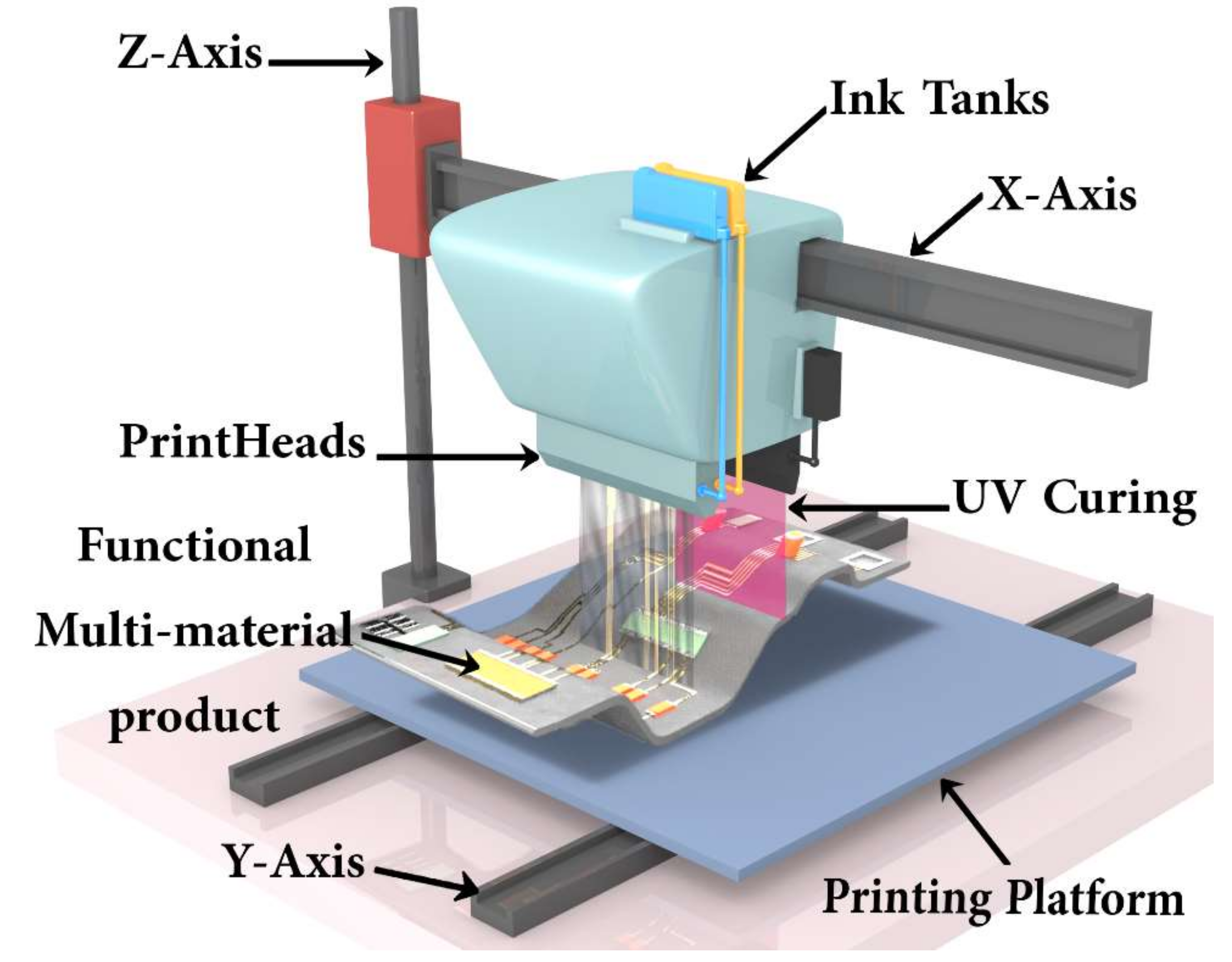

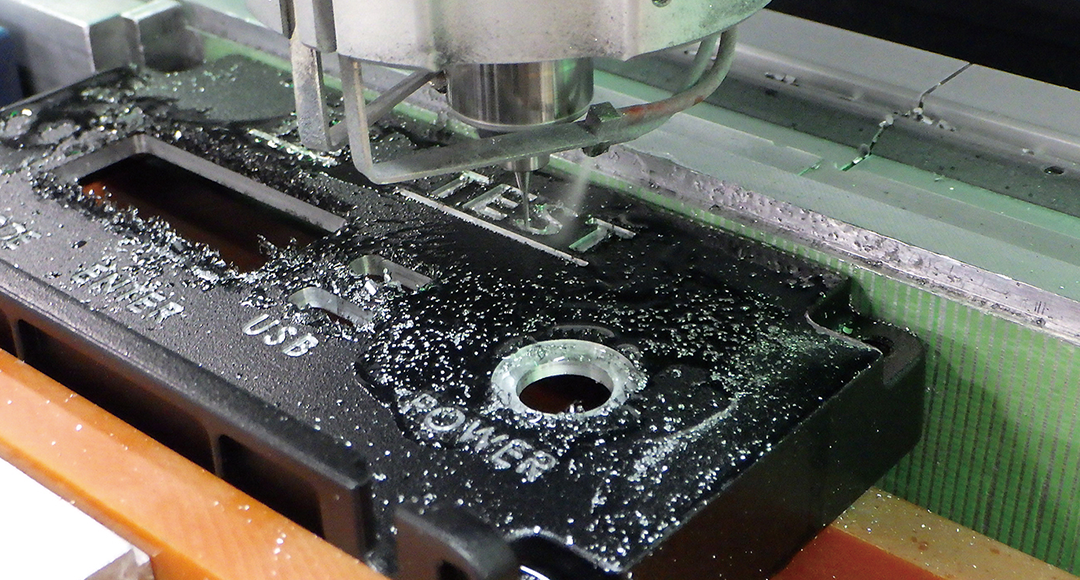

Basically, it uses tiny nozzles to spray ink onto the plastic surface. These nozzles are so small, they make my patience with slow internet speeds look positively gigantic. The ink dries or cures (more on that later) and voilà! You have a beautifully decorated (or at least, clearly marked) plastic part.

Why Plastic? Why Now?

You might be asking, "Why bother printing on plastic in the first place? Isn't paper good enough?" Well, no. No, it's not. Especially not when you need something durable, waterproof, and, you know, plastic. Think about all the plastic stuff around you: your phone case, your car's dashboard, that creepy plastic doll your aunt gave you that seems to follow you with its eyes. All potential candidates for some sweet inkjet action!

And why now? Because technology, my friends, is always advancing! We're talking faster printers, better inks, and more creative applications than you can shake a stick at. Plus, regulations are getting stricter about traceability and product identification, which means more and more manufacturers are turning to inkjet printing to put serial numbers, barcodes, and other vital information directly onto their plastic parts. It's not just about looking pretty; it's about being responsible (and avoiding hefty fines!).

The Nitty-Gritty (but Still Funny) Details

So, how does this plastic printing magic actually happen? Let's dive into the slightly more technical, but still hopefully entertaining, details:

- The Ink: This isn't your average ballpoint pen ink. We're talking specially formulated inks designed to adhere to plastic. Think of it as super glue for color! These inks often contain pigments or dyes that are resistant to fading, scratching, and even chemical exposure. Imagine a logo that can survive a nuclear apocalypse... okay, maybe not that far, but you get the idea.

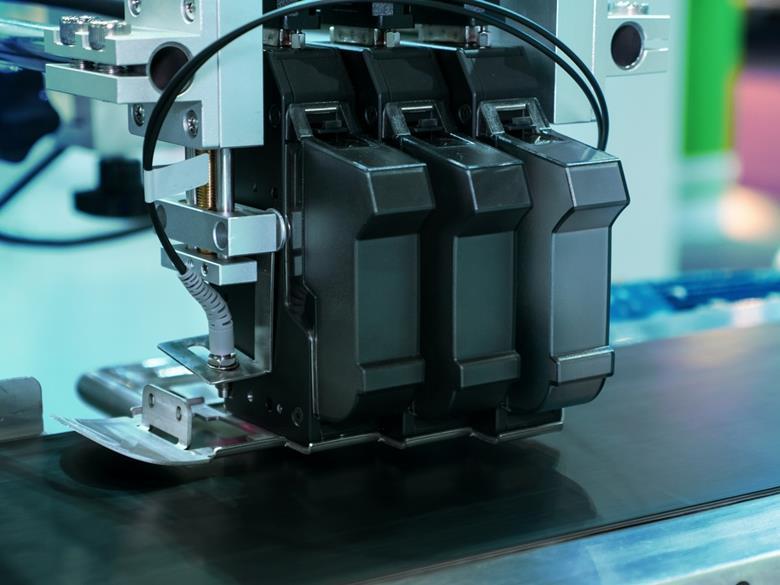

- The Printer: These aren't your grandma's inkjet printers. Industrial inkjet printers are built for speed, precision, and durability. They can handle high-volume printing, complex designs, and even variable data (like serial numbers that change with each print). Think of them as the Usain Bolt of the printing world.

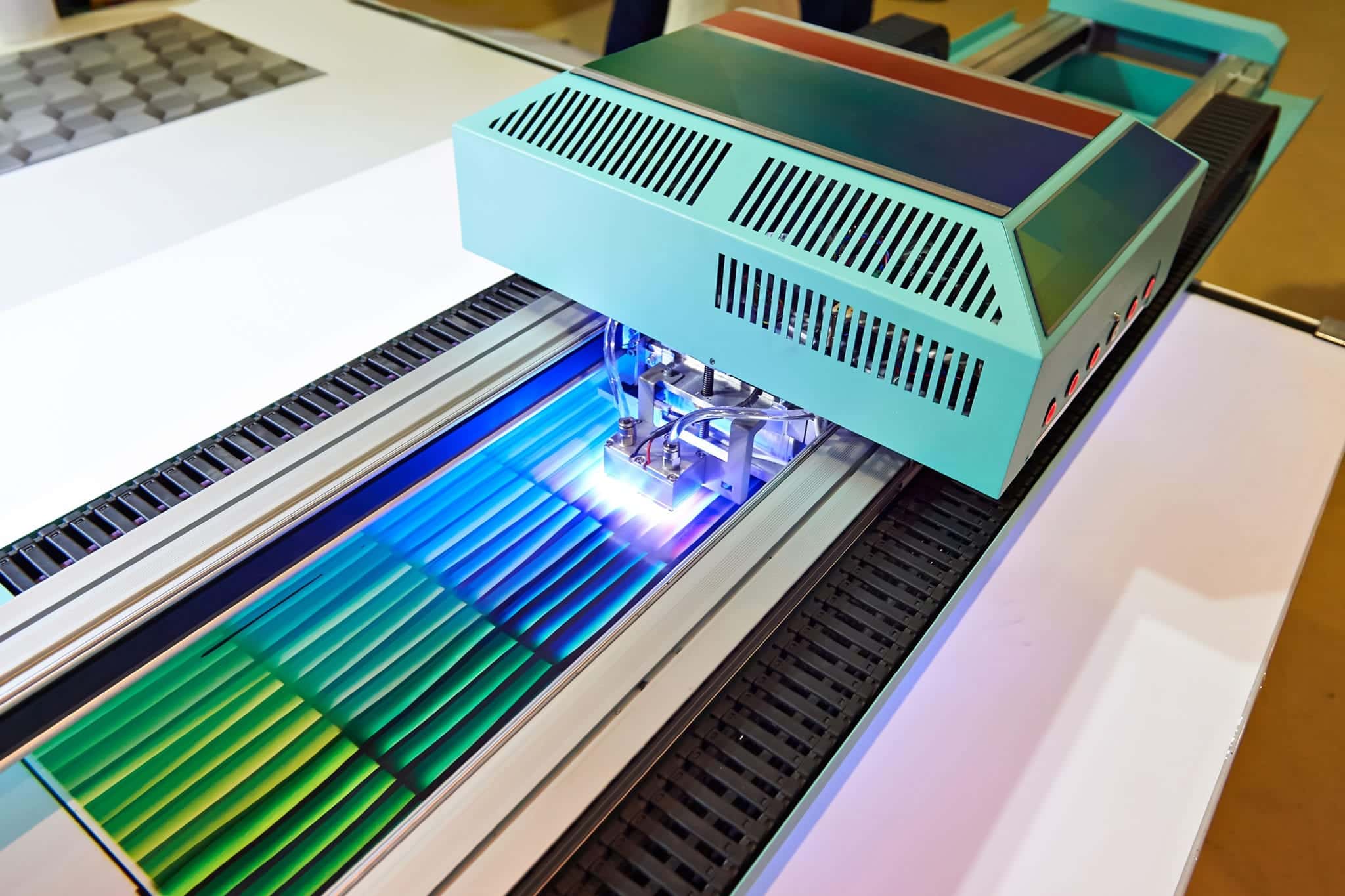

- The Curing Process: Once the ink is applied, it needs to be cured or dried. This can be done using various methods, such as UV light, heat, or even electron beams (yes, electron beams! It's like science fiction come to life!). Curing essentially hardens the ink, making it resistant to smudging, scratching, and all sorts of other nasty things. It's like giving your ink a superhero shield.

Types of Inkjet Technologies: A Quick and Quirky Overview

Believe it or not, there's more than one way to spray ink onto plastic! Here are a couple of the most common inkjet technologies:

- Continuous Inkjet (CIJ): Imagine a constant stream of ink droplets, some of which are deflected onto the plastic while others are recycled. It's like a water fountain that only sprays the people it likes. CIJ is great for high-speed printing on a variety of surfaces, even slightly uneven ones.

- Drop-on-Demand (DOD): This is where ink droplets are only ejected when needed. It's like a polite printer that doesn't waste any ink. DOD is more precise than CIJ and can produce higher-resolution images.

The Advantages (and a Few Minor Annoyances)

So, why are companies so hyped about digital inkjet printing on plastic? Well, here are a few of the advantages:

- Flexibility: You can print almost anything you want, from simple text to complex graphics. It's like having a digital artist at your fingertips.

- Speed: Inkjet printing can be incredibly fast, especially with CIJ technology. This means you can churn out a lot of printed plastic parts in a short amount of time. Perfect for mass production and meeting those tight deadlines.

- Cost-Effectiveness: While the initial investment in equipment can be significant, inkjet printing can be more cost-effective than other printing methods in the long run, especially for short to medium runs.

- Environmentally Friendly: Compared to some traditional printing methods, inkjet printing can be more environmentally friendly, as it produces less waste and uses less energy. You can feel good about printing your plastic parts (within reason, of course. Maybe don't print a whole plastic island).

Of course, no technology is perfect. Here are a few potential drawbacks:

- Ink Costs: Specialized inkjet inks can be expensive. It's like buying gourmet coffee beans for your printer.

- Maintenance: Inkjet printers require regular maintenance to keep them running smoothly. Nozzles can clog, and ink lines can get dirty. Think of it as giving your printer a spa day... except instead of relaxing music and cucumbers, it's solvents and compressed air.

- Substrate Compatibility: Not all plastics are created equal. Some plastics are easier to print on than others. You might need to pre-treat the plastic surface to ensure proper ink adhesion. It's like making sure your plastic is wearing the right primer before applying makeup (printing, in this case, being the makeup).

The Future is Plastic (and Printed!)

Digital inkjet printing on plastic parts is only going to become more prevalent in the future. As technology improves and costs decrease, we'll see it used in even more innovative and creative ways. Imagine personalized plastic packaging, customized car interiors, and even printed electronics directly on plastic substrates. The possibilities are truly mind-boggling!

So, the next time you see a logo or serial number on a plastic part, take a moment to appreciate the magic of digital inkjet printing. It's a technology that's quietly revolutionizing the manufacturing world, one perfectly printed droplet at a time. And who knows, maybe one day you'll even be printing your own tiny cat hats on plastic. The future is weird, and it's probably going to be printed on plastic.

In Conclusion: It's Not Just Ink on Plastic!

So there you have it, folks! A whirlwind tour of the wacky and wonderful world of digital inkjet printing on plastic parts. It's a bit more complicated than just slapping some ink on plastic, but hopefully, I've made it at least a little bit entertaining. Now, if you'll excuse me, I'm going to go see if I can find a plastic spork to print a motivational quote on. Wish me luck!

![Benefit Of Digital Printing On Plastics [FREE WHITE PAPER] - Digital Inkjet Printing On Plastic Parts](https://ppsnordic.com/wp-content/uploads/2019/05/PPS-digital-direct-printing-products-large-600x381.jpg)