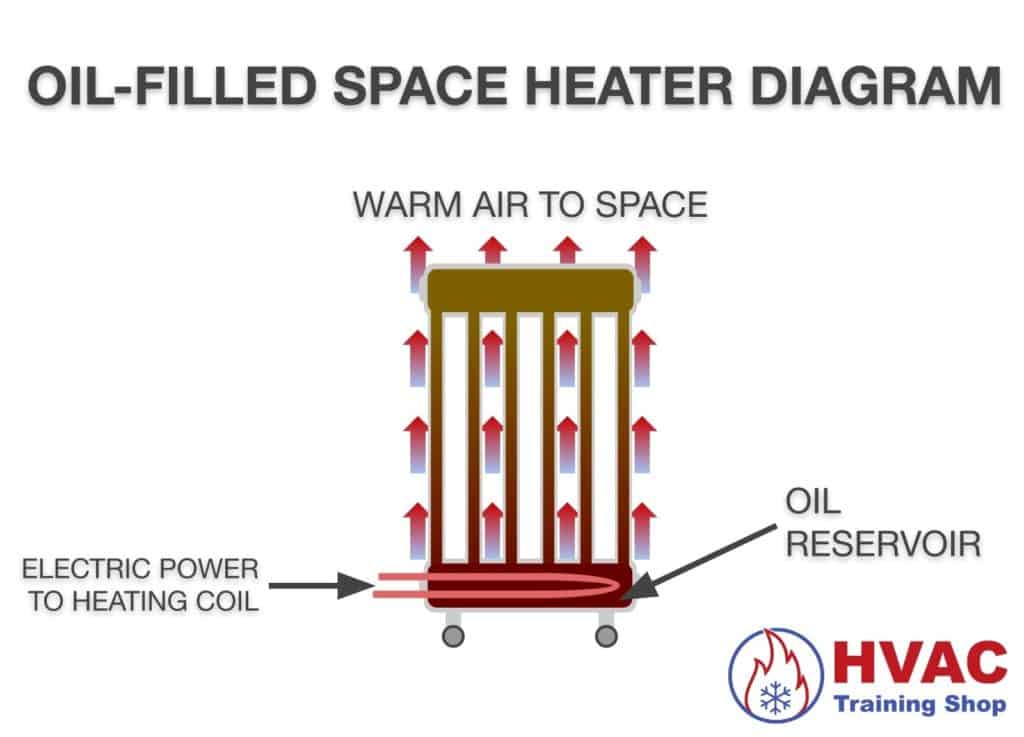

An oil-filled heater, also known as an oil-filled radiator or column heater, is a common household appliance used for supplemental heating. Despite its name, the oil within the heater is not burned; rather, it acts as a heat reservoir and transfer medium. Understanding the operational principles of this device can provide insights into its energy efficiency and appropriate usage.

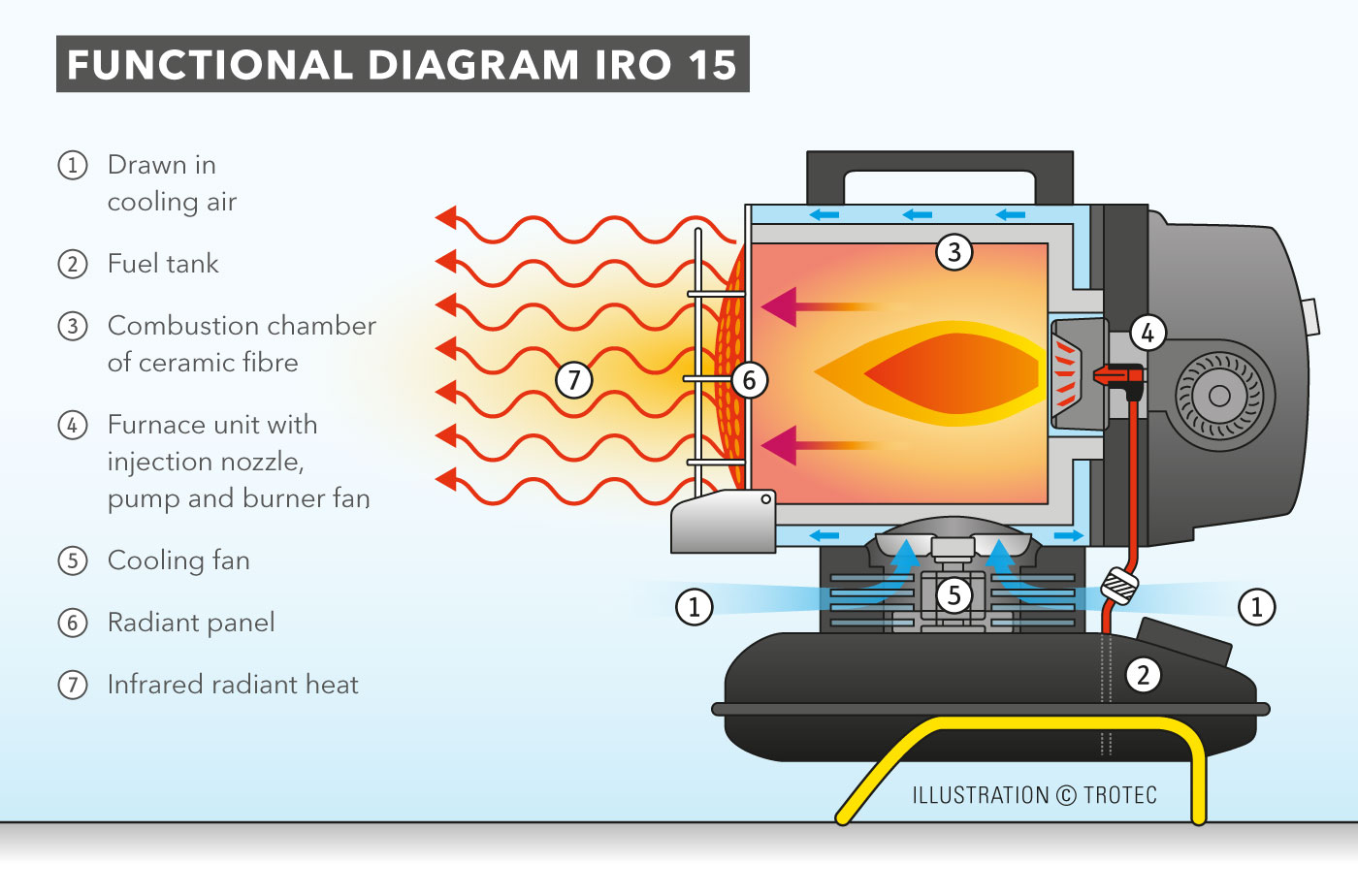

The Core Components

An oil-filled heater comprises several essential components that work in concert to generate and distribute heat. These components include:

- Heating Element: An electrically resistive element submerged within the oil. This element converts electrical energy into thermal energy through the Joule heating effect.

- Thermic Oil: A specially formulated oil designed to efficiently transfer heat and withstand high temperatures without degrading or becoming volatile. Mineral oil is a common choice due to its thermal stability and non-corrosive properties.

- Metal Fins or Columns: The external structure of the heater consists of multiple fins or columns. These significantly increase the surface area available for heat dissipation into the surrounding environment.

- Thermostat: A temperature-sensitive control mechanism that regulates the electrical current to the heating element. It maintains the desired room temperature by cycling the heater on and off.

- Safety Features: Overheat protection mechanisms, such as thermal cutoffs, are incorporated to prevent the heater from reaching dangerously high temperatures, which could pose a fire hazard. Tip-over switches are also common, shutting off the heater if it is accidentally knocked over.

- Control Panel: Allows the user to adjust the thermostat setting and power level. Some models include timers and remote control functionality.

The Heating Process: A Step-by-Step Explanation

The heating process within an oil-filled heater can be broken down into a series of distinct steps:

1. Electrical Energy Input

The process begins when the heater is plugged into an electrical outlet. When switched on, electrical current flows to the heating element. The amount of electrical current is often adjustable via the power level settings on the control panel. Higher power settings allow more current to flow, resulting in faster heating.

2. Joule Heating

As the electrical current passes through the resistive heating element, electrical energy is converted into thermal energy. This phenomenon is known as Joule heating, where the electrical resistance of the element opposes the flow of current, causing it to heat up. The heat generated is directly proportional to the square of the current and the resistance of the element (P = I2R, where P is power, I is current, and R is resistance).

Example: A heating element with a resistance of 20 ohms carrying a current of 5 amps will generate 500 watts of heat (52 * 20 = 500).

3. Oil Convection

The heat produced by the heating element is transferred to the surrounding thermic oil. The oil, being a fluid, circulates within the heater via convection. The oil near the heating element heats up, becomes less dense, and rises. Cooler, denser oil sinks to the bottom, creating a continuous循環 of circulating warm oil. This convective circulation ensures that the heat is distributed evenly throughout the entire volume of oil within the heater.

4. Heat Radiation and Convection from Fins

The heated oil, in turn, transfers its thermal energy to the metal fins or columns of the heater. These fins are designed to maximize the surface area in contact with the surrounding air. The heat is then dissipated into the room primarily through two mechanisms: radiation and convection.

- Radiation: The fins emit infrared radiation, which directly heats objects and surfaces within the room. The intensity of radiated heat depends on the temperature of the fins.

- Convection: The fins also heat the air in contact with them. This warm air rises, creating a convective current that circulates throughout the room, distributing the heat more evenly.

5. Thermostat Regulation

The thermostat plays a crucial role in maintaining a consistent room temperature. The user sets the desired temperature on the thermostat. When the room temperature falls below the setpoint, the thermostat allows electrical current to flow to the heating element, initiating the heating process. Once the room temperature reaches the setpoint, the thermostat interrupts the current, turning off the heating element. This cycle repeats, maintaining a relatively stable temperature.

6. Safety Mechanisms

Overheat protection is a vital safety feature. If the heater's internal temperature exceeds a predetermined threshold, a thermal cutoff switch activates, interrupting the electrical current to prevent overheating and potential fire hazards. Similarly, a tip-over switch automatically shuts off the heater if it is accidentally tipped over, preventing it from continuing to operate in an unsafe position. These safety features are essential for preventing accidents and ensuring safe operation.

Advantages and Considerations

Oil-filled heaters offer several advantages over other types of space heaters:

- Even Heat Distribution: Due to the convective circulation of the oil and the large surface area of the fins, oil-filled heaters tend to provide more even and consistent heat distribution compared to forced-air heaters.

- Silent Operation: Unlike forced-air heaters that rely on fans, oil-filled heaters operate silently, making them ideal for bedrooms and other quiet spaces.

- No Exposed Heating Elements: The heating element is enclosed within the oil, reducing the risk of burns and fire hazards compared to heaters with exposed heating coils.

- Residual Heat: Oil retains heat for a considerable time after the heater is switched off, providing continued warmth and potentially reducing energy consumption.

However, there are also some factors to consider:

- Slower Heating: Oil-filled heaters typically take longer to heat up a room compared to forced-air heaters, as the oil needs to be heated first.

- Heavier Weight: They tend to be heavier and less portable than other types of space heaters.

- Initial Odor: Some new oil-filled heaters may emit a slight odor during the initial few uses, which is generally harmless and dissipates over time.

Practical Advice for Everyday Life

To maximize the effectiveness and safety of an oil-filled heater, consider the following tips:

- Placement: Position the heater in a central location within the room to promote even heat distribution. Avoid placing it near flammable materials or obstructing airflow around the fins.

- Thermostat Setting: Experiment with the thermostat setting to find a comfortable temperature that balances warmth and energy efficiency. Lowering the thermostat by a few degrees can significantly reduce energy consumption.

- Regular Cleaning: Periodically dust the fins to maintain efficient heat transfer. A buildup of dust can impede heat dissipation and reduce the heater's performance.

- Safety Checks: Inspect the power cord for any signs of damage before each use. Ensure that the heater is placed on a stable, level surface to prevent accidental tip-overs.

- Supplemental Heating: Use the oil-filled heater as supplemental heating in specific rooms rather than relying on it to heat an entire house, especially during peak heating periods. Combine it with other heating strategies such as insulation and draft proofing.

- Understand the Oil: The oil inside the heater is a closed system and should not require replacement. If you suspect a leak, discontinue use immediately and consult a qualified technician.

By understanding how an oil-filled heater works and following these practical tips, you can effectively utilize this appliance to provide comfortable and safe supplemental heating in your home.

![Oil Filled Heater vs Electric Heater [Pros & Cons] - YouTube - How Does An Oil Filled Heater Work](https://i.ytimg.com/vi/n7TJARyj5KM/maxresdefault.jpg)